Seeing cars like yours make it very difficult for me to try and stick with stock wheels hahaha So pimp!

Announcement

Collapse

No announcement yet.

My DC5R

Collapse

X

-

Honestly, no. After the research I've done, and the parts I'll be putting on the engine, I should be making more peak power, a fair bit more torque and still be able to rev out to 8k RPM. All with the advantage of running basically an OEM Honda engine. Out of my parts, the throttle body is the only non-OEM item I am using.Originally posted by ChargeR View PostNice progress. Did you ever consider swapping the head off your K20 onto the K24? Just curious about your reasoning as I have been having dreams of K24s for a while now, and tossing up between doing a Frankenstein or just putting the K24A2 as is.

All up, I think I'm up to about 3k in parts, and I'm fitting it with some friends, so labour is going to be a fair bit lower.

Considering most K24/20's go for about 8k+, this is MUCH cheaper, and is still going to net me fairly noticeable gains over the K20... and again OEM reliability.

I also have a K24a3.

After taking the intake and exhaust manifolds off, everything looks VERY Clean (Thanks BYP boys).

Internet is evil... it gives you so many idea.Originally posted by Peachy View PostSeeing cars like yours make it very difficult for me to try and stick with stock wheels hahaha So pimp!

Yep... sorted.Originally posted by Norm View Posthope your boring your rbc tb port to 70mm to match the adaptor. If you don't you'll get a lot of turbulence.

In the plastic bubble wrap bag.Originally posted by felixR View PostWhere is this in the pic and what does it do?

Basically what the i in "i-Vtec" stands for.

For the K24 I'll only be running 40' (adjustable with K-pro), as if you run the full 50' you have the possibility of piston to valve touching... not a good thing.

K24a3 only has a 25' VTCLast edited by 45SET; 15-10-11, 04:42 PM.

Comment

-

The cost of doing k20/k24 isnt much worth it compared to gains. It might yield extra power from 6000rpm onwards (3-5kw) the cost involve could be spent elsewhere.Originally posted by ChargeR View PostNice progress. Did you ever consider swapping the head off your K20 onto the K24? Just curious about your reasoning as I have been having dreams of K24s for a while now, and tossing up between doing a Frankenstein or just putting the K24A2 as is.

Upgrade the valve springs/ VTC/ k20a oil pump mod and try source a late k20a intake cam. This accompanied with RBC +70mm and some decent headers will net 150-155kw atw. A good tune will help get those power levels.

Hope this helps future K24 builds Last edited by fatboyz39; 16-10-11, 12:06 AM.BYP Racing & Developments

Last edited by fatboyz39; 16-10-11, 12:06 AM.BYP Racing & Developments

Built. Tuned. Driven

Want to go fast? Come see us! e: jimmy@bypracing.com ph: (02) 9757 4757

Comment

-

VTC- You'll find that k24a3 max will like 40VTC. Last edited by fatboyz39; 16-10-11, 12:06 AM.BYP Racing & Developments

Last edited by fatboyz39; 16-10-11, 12:06 AM.BYP Racing & Developments

Built. Tuned. Driven

Want to go fast? Come see us! e: jimmy@bypracing.com ph: (02) 9757 4757

Comment

-

So... today was a VERY productive day with the K24.

This was the 2nd week in a row that I had worked on the K24. Last week we basically just pulled off some parts, and tidied a few things up... nothing productive.

This week on the other hand... We started with this

And these parts needed to be fitted

The day started by pulling the rocker and timing covers off. The engine looks very clean inside

(Cam on the right of the above pic is the 25' VTC)

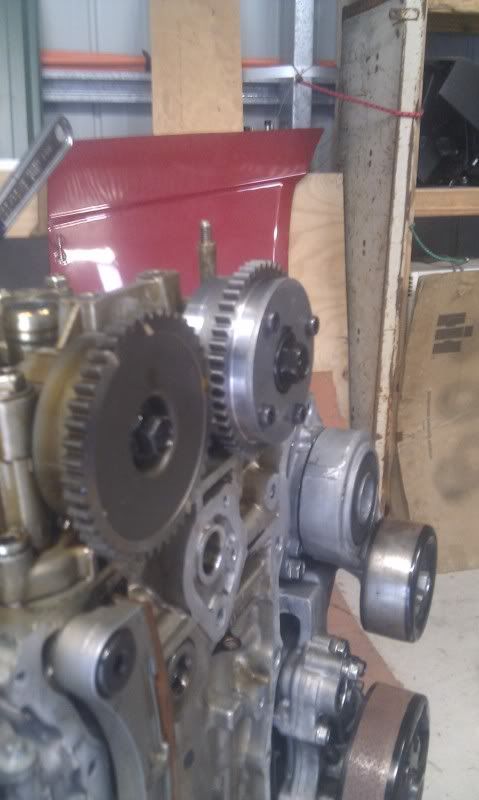

After we took the covers off we had to remove both the timing chain, and the oil pump chain (Refer above picture), as I'll be running a K20 oil pump rather then the K24 one... and after I compared the two, I was happy I made that decision

Top is the K24 oil pump, bottom is the K20 oil pump (This needs to be slightly modified). As you can see, K20 item is MUCH smaller, and uses MUCH less parts... so should make a few extra KW.

Here is a picture of the crank... again... nice and clean.

K20 oil pump fitted

After this, we moved onto fitting the 50' VTC. This is a fairly basic procedure, as it's just loosening the old 25' VTC, then replacing it with the 50' VTC.

After the VTC was fitted, we fit everything back together, which was a little bit trickier then we thought, as we were worried about stretching both the timing chain and the oil pump chain. But once everything was fitted, everything lined up, and nothing was stretched

Here is a pic of everything fitted before we put all the covers back on.

We put the J's Racing K20 Baffled sump on, which was basically the only "issue" from the entire day! The K24 sump is made of a thin steel, where as the K20 sump is made of a cast metal, so we couldn't use the bolts from the K24 sump. As I found out Hondabond is great stuff, so I'll be taking the bolts from my current K20 when I take it out in 2 weeks!

Final pics with RBC and Skunk2 70mm throttle body fitted!

I'd like to thank Jimmy for BYP, as he has helped me a fair bit with parts and information on my current build.

If anyone has any questions, let me knowLast edited by 45SET; 22-10-11, 08:58 PM.

Comment

-

Did you guys plug up the oil gallery when running the k20a oil pump mod? Sorry i should of mention about those sump bolts BYP Racing & Developments

BYP Racing & Developments

Built. Tuned. Driven

Want to go fast? Come see us! e: jimmy@bypracing.com ph: (02) 9757 4757

Comment

-

Good progress!

Thanks for the reply, I was more talking about a pretty basic K20 head swap with just the basics done to make it work, nothing crazy with all forged internals or anything. Specifically I had ideas of a putting together a mild motor with just 09+ TSX pistons, aftermarket rods, the better flowing K20 head, and some aftermarket cams. I like your concept of staying basically mostly OEM K24A3 parts, and realistically it is probably the path I would follow too.Originally posted by 45SET View PostHonestly, no. After the research I've done, and the parts I'll be putting on the engine, I should be making more peak power, a fair bit more torque and still be able to rev out to 8k RPM. All with the advantage of running basically an OEM Honda engine. Out of my parts, the throttle body is the only non-OEM item I am using.

All up, I think I'm up to about 3k in parts, and I'm fitting it with some friends, so labour is going to be a fair bit lower.

Considering most K24/20's go for about 8k+, this is MUCH cheaper, and is still going to net me fairly noticeable gains over the K20... and again OEM reliability.

I also have a K24a3.

I meant to type K24A3, I have just been reading too many US threads and K24A2 and A3 have become interchangeable in my head since they are so similar .

.

Thanks Jimmy, helps a lot and I think if I did do a K24A3 (in anythingOriginally posted by fatboyz39 View PostThe cost of doing k20/k24 isnt much worth it compared to gains. It might yield extra power from 6000rpm onwards (3-5kw) the cost involve could be spent elsewhere.

Upgrade the valve springs/ VTC/ k20a oil pump mod and try source a late k20a intake cam. This accompanied with RBC +70mm and some decent headers will net 150-155kw atw. A good tune will help get those power levels.

Hope this helps future K24 builds

) I would leave it stock except for the mods you mention and a baffled sump to start with

) I would leave it stock except for the mods you mention and a baffled sump to start with  .

.

Comment

-

Like Jimmy said, for the extra work/money/parts that needs to be done to fit the K20 head, you may as well spend the money else where (Such as brakes). Once the engine is in, I'll give another update with how different the car is. I'll be running a base map for a little while, as I'll need to find a tuner in Brisbane I'm happy with. I've spoken to a few, and just from the conversation we've had about the K24 swap, I decided I didn't want to have them tune my car. At the moment, I'm seriously considering a drive down the Sydney for Jimmy to work his magic on the dyno (As I've been told I NEED to take 2 weeks off from work).Originally posted by ChargeR View PostThanks for the reply, I was more talking about a pretty basic K20 head swap with just the basics done to make it work, nothing crazy with all forged internals or anything. Specifically I had ideas of a putting together a mild motor with just 09+ TSX pistons, aftermarket rods, the better flowing K20 head, and some aftermarket cams. I like your concept of staying basically mostly OEM K24A3 parts, and realistically it is probably the path I would follow too.

I meant to type K24A3, I have just been reading too many US threads and K24A2 and A3 have become interchangeable in my head since they are so similar .

.

After working on the engine yesterday, I saw how it would be relatively easy to change the cams in the K24... so in the future, I might look into the K20 intake cam, if I'm after a little more power.

Comment

-

LOL wish my boss would say that!Originally posted by 45SET View Post(As I've been told I NEED to take 2 weeks off from work).

so in the future, I might look into the K20 intake cam, if I'm after a little more power.

Wouldn't it be better to do the K20 intake cam now, future proofing your self so to speak and saving another tune?

Comment

-

Because then I would have nothing to get excited about in the futureOriginally posted by Flippit View PostLOL wish my boss would say that!

Wouldn't it be better to do the K20 intake cam now, future proofing your self so to speak and saving another tune?

But on a serious note... I've spent more then enough money on the engine at the moment.

Comment

-

*UPDATE*

So yesterday (5/11/2011) was d-day for the K20. I reved it out to 8,500RPM for the last time, and it still bought a smile to my face (Almost 5 years on)

I turned up at my friends place (Kurt) at 8am, and we waited for Jason to rock up before we started pulling things part.

The day started by by loosening the hub nut (Which is a 36mm for those playing at home). Now... Kurt has every tool imaginable in his shed (Including a hoist)... but didn't have a 36mm bit, so while Kurt and his dad drained all the liquids from the engine, Jason and I went for a drive to find the bit... the joys of working on cars!

We returned with the bit, and started to try and take off the bolts... simple right... wrong. After breaking two breaker bar in the space of 10 min trying to remove the bolts, Kurt decided he wanted to go buy a new ratchet anyway, so again, went out to buy parts.

He came back with a 600ft/pd ratchet, that removed the bolts in a matter of seconds. With his new toy in hand, when ever a bolt needed removing, Kurt was on the scene!

After this we needed to remove remove the sub frame. Now there are two ways of doing this. One, remove the brake assembly from the sub frame, or remove the callipers from the brakes, and drop the brake assembly with the sub frame. As you can see from the below, we chose the latter.

This process was fairly easy, and we have followed the RSX and TSX manuals for the entire process (Downloadable from the internet). I am retaining power steering and aircon. Aircon has not been removed from the car, and was removed from the K20, and then zip tied to a part of the engine so I don't need to worry about degassing it. As the front and rear engine mounts are connected to the sub frame, the engine was now only on the two side mounts.

Underside of the engine with no sub frame

Next up, we needed to remove the wiring harness. Again, if you follow the manuals (RSX), it's fairly basic, and just make sure there is nothing connected to the engine. Only problem we experienced here was that the knock sensor on the front of the engine broke as we removed it! But upon closer inspection, it had either been broken for a while, or just needed a slight touch to break. As we had a hoist, dropping the engine was fairly basic.

Then came the fun part! The Integra was raised on the hoist as high as it would go, and the K24 was rolled over on the engine stand so it was sitting next to the K20. So to save many headaches, I've decided that I'm going to run all the K20 pulleys (Crank, alternator, air con, power steering and water pump). So these where all removed from the K20 and K24, and swapped. One thing to note, you can't JUST swap the K24 and K20 water pumps, you need to swap over the entire gallery, as the pumps are slightly different (Out by about 2mm).

So, it was 2pm, we had removed the K20 from the car, the K24 was basically finished and almost ready to go in the car. Kurt, Glen, Jason and I were all getting a little excited at the prospect of actually doing a K20-to-K24 swap into a DC5R in 1 day... but... as everyone that has done something like this know, nothing runs smoothly.

Glen started putting the spark plugs into the K24 (As it didn't come with any, which I thought was rather odd, as it still had the coil packs). He spaced the plugs, and went to put the one into cylinder 1, when he said to me "Robi, are you sure these are the right plugs, this doesn't want to go in". I confirmed they were the right plugs, and that 3 people had looked over the part number to confirm it. So he moved onto cylinder 2, and it went in perfectly... as did 3 and 4. He went back to cylinder 1, and tried again... and confirmed our worst fears... the spark plug port had been threaded, and was like that before we even got the engine.

We sat around for about 20 min... all of us rather bummed at the fact that the worst thing that had happened during the entire build to this point was that we snapped an ABS cable while removing the callipers. While we were all sitting around, some options were thrown around:

- Loctight the spark plug into cylinder 1

- Remove the head and have it helicoiled

- Remove the K20 head and put it on the K24

Honestly, option 1 was never really an option. It would have meant that I would still have to remove the head eventually, and it would probably end up costing more in the long run.

Option 3 was considered for about 5 min. Then we realised that I still want to sell the K20 to recoup a little bit of money from the build, and I would still need to buy a new head gasket... so he wasn't going anywhere anyway.

Option 2 was the option that was finally decided on. So removing of the head begun. The TSX manual came in very big use for this process, as you need to remove the head bolts in a particular order, and only do quarter turns.

Here are all the valve train components.

Here is the head. Spark plug port on the left is the sinister port!

Here is the bottom end.

So during the week, the spark plug port is going to get helicoiled, and next weekend we'll put the head back on to the engine and fit it in the car. At the moment the car is sitting on the hoist, with no engine, and no sub frame. The K20 is sitting under the car, and the K24 next to it. It was rather depressing see the car in this state, as I have so much pride in it, and I was hoping to actually drive it home that day (And at 2pm, it looked like it was going to happen).

I'll update the thread next weekend once everything is back together. If anyone has any questions let me know.

Thanks

Robi

Comment

Comment