yeah I cant wait till finished too.........then i'll buy it of you.......lolz

Announcement

Collapse

No announcement yet.

S2000 - My Story

Collapse

X

-

Picking up on the oil cooler install, as mentioned from the very beginning, the oil temp sensor is the only PITA part of the entire install. Issues I experienced were;

-where to found sensor

-typical places to mount said sensor gave me mixed results - volatility in temp readings in street conditions

-difficulty in mixing different region parts to work together, IE defi sensors utilise BSPT/PT(British) whereas Earls being American all use NPT etc

I even bought a spacer fitting by Trust/Greddy, and that was a failure where the threads were too lose, and didnt screw in enough on the defi (female side) as well as on the male side too....

Since I already have the part, and it is indeed useless to me, Im going to get both ends trimmed off to see fitment.... I'll get pics of this later on, as I lost all my phone photoes...

Anyways, I thought I do this post to anyone reading to go for the Greddy sandwich plate... As I mentioned initially, it is the perfect design for where the thermostat is located, offers two ports for sensors. It's only downfall is the low operating thermostat, and if I had to be picky, it could use a thicker O ring like the mocal. That is where the Mocal excels, it's O ring is 4, maybe 5 times larger than the Greddy, an it does have a high temp thermostat that closes at 93c!

Saru, another S2000 owner here has installed the Trust Oil Cooler kit and is scratching his head why the oil temp readings are mysteriously low.

I've already explained in a previous post how the Mocal sadnwich plate operates, but I'd like to explain a key difference is how each thermostat moves to direct oil...

Firstly the Mocal sandwich plate, oil leaves the block and either falls into the oil cooler hose, or through the other side that goes into the oil filter and then directly back ino the engine block via the center hole... Yeah Mocal Technician, there really is just 5% flow of oil when below 93c aye....

Now the Greddy sandwich plate. Lets see some pictures first!

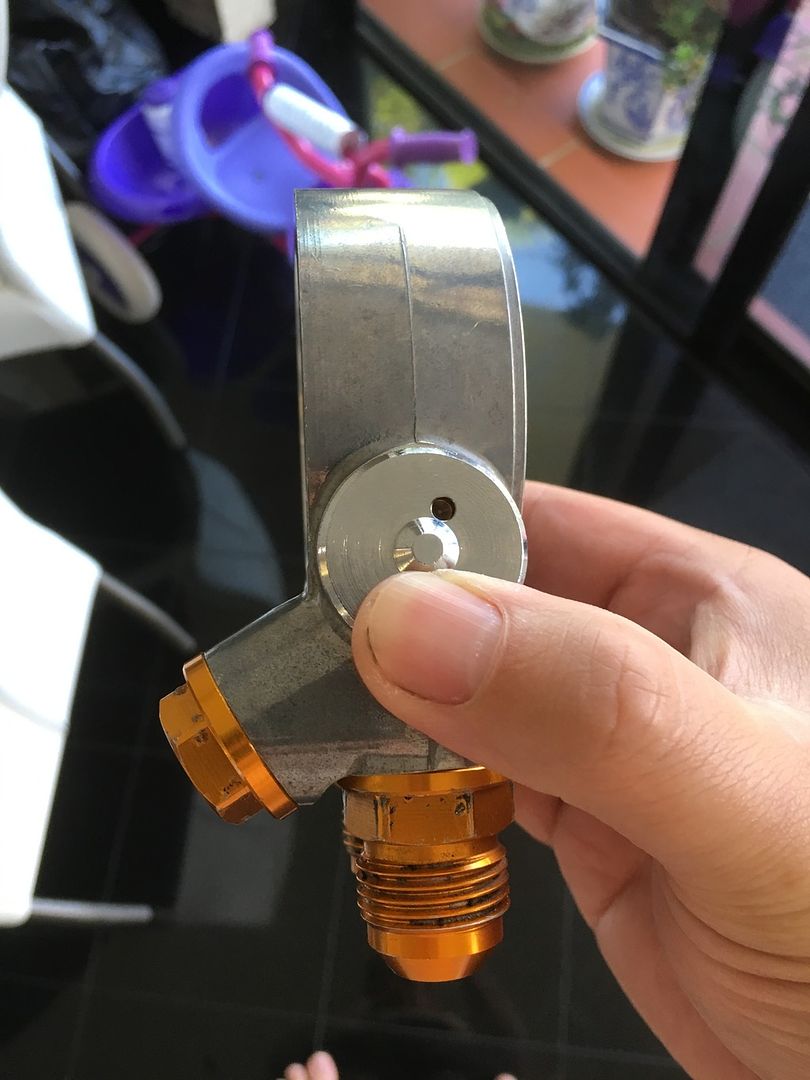

This is the side shot of the sandwich plate. Left side is where oil filter screws. Right side faces the engine block.

This side mates to the engine block. The key difference of design starts here. See here, there is only one place for the oil to go towards, and that is towards the oil cooler hose. Even on this pic, you can see a small hole where you can see my yellow skin. This is where the oil flows through when below 70C, as well as oil going towards the cooler.

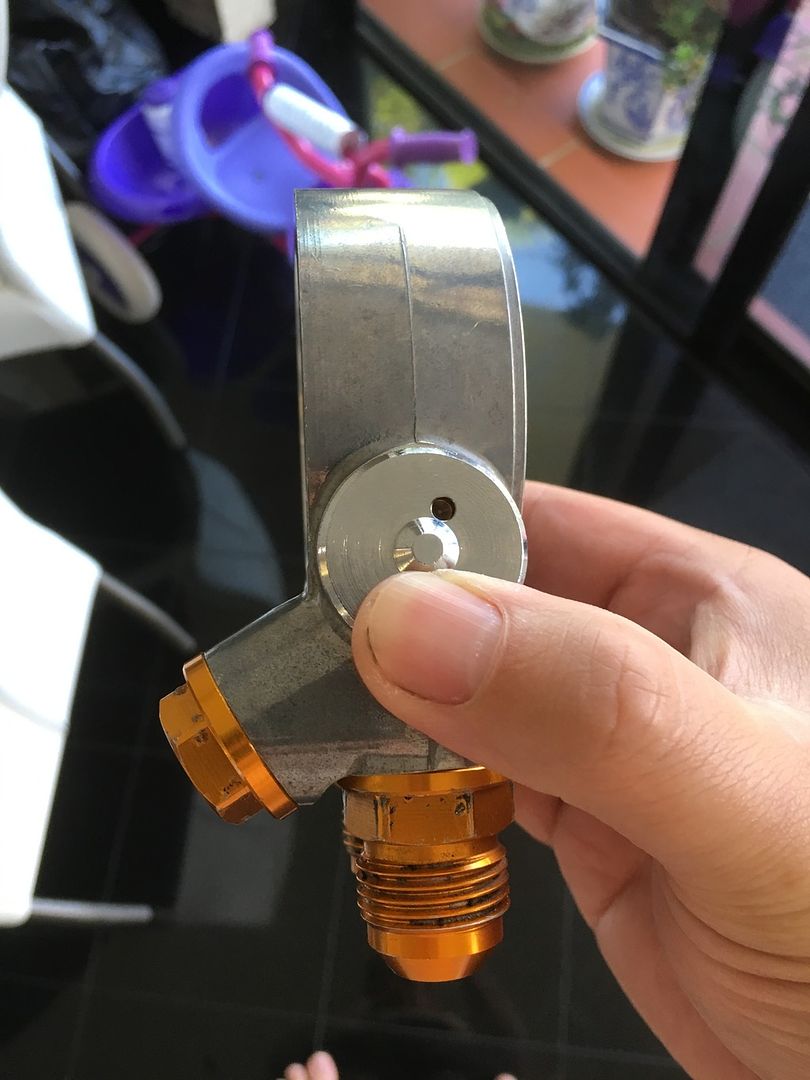

This is the other side, the side where the oil filter faces. Here is a better shot of that hole where oil flows through when below 70C

So I also tested the thermostat and what happens!

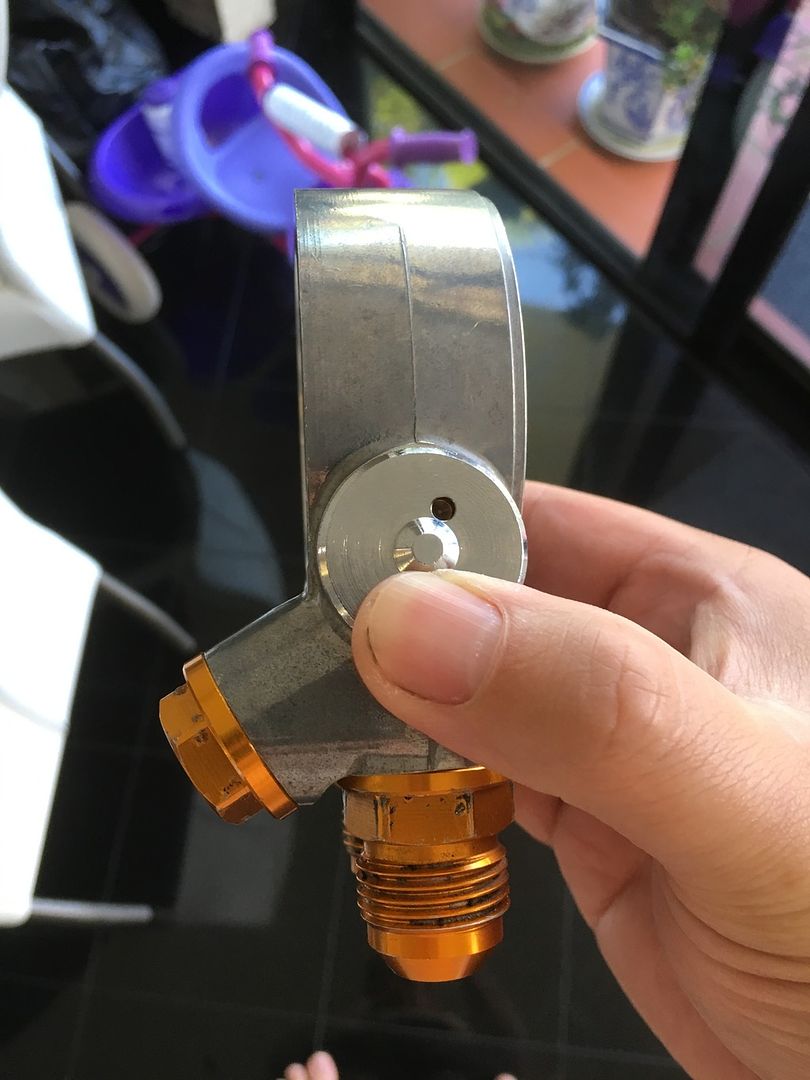

Here we are over 70C, and the thermostat begins to move. It moves to the left, thus closing and block off all flow of oil to the hole. The oil can now only be directed to the oil cooler hose, and thus through the cooler to be cooled.

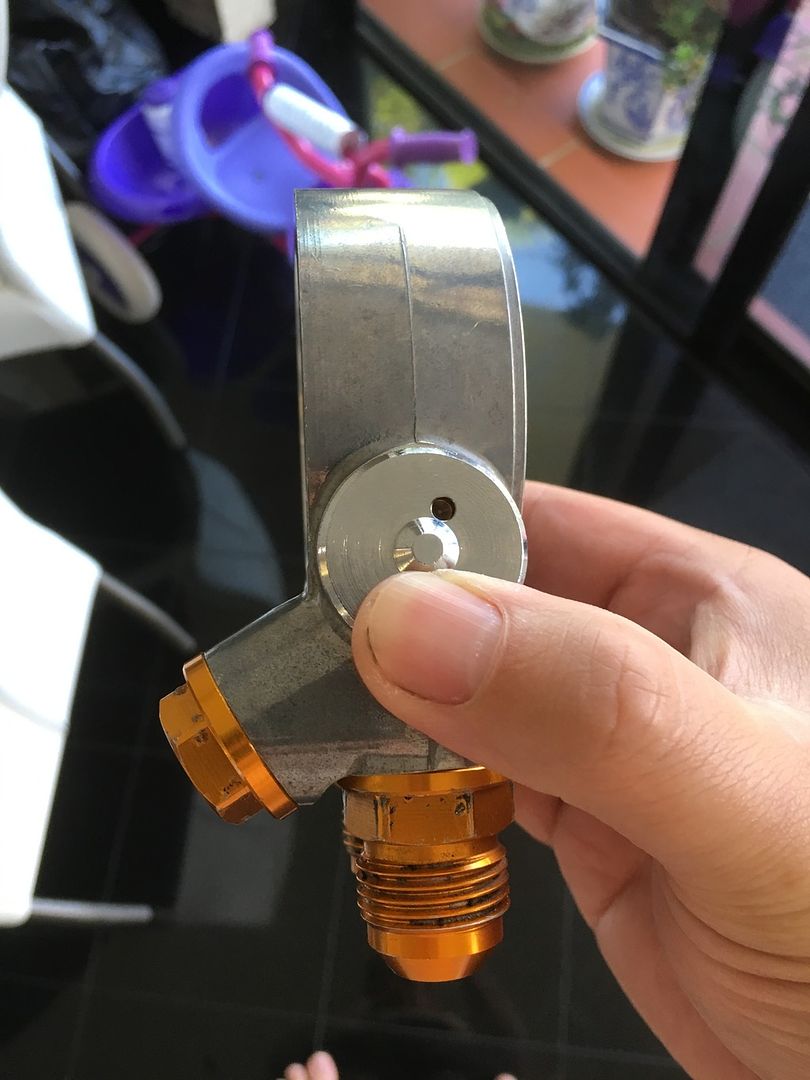

temps are now over 80C, and you can see the thermostat has completely moved over and now 100% flow of oil going through to the cooler!

I did record a couple vids of the thermostat moving but they're taking ages to upload....

Anyways the important shit is above... SO looking at all that. Referring to this pic again

The hose at the bottom collects HOT oil from the engine, goes to the cooler, then the cooler disperses the now cooled oil fmor the top hose and back into the sandwich plate (top) Looking at Saru's pic here

His temp sensor is giving readings on what the temp is AFTER cooler, hence the reason why his defi ZD shows lower than expected reading.

There are many arguments to which side you want to run your temp sensor. In an ideal world where it is easy to setup and cost effective, you'd want to run a temp sensor before and after! But due to constraints in life, The oil temp sensor I would personally put it on the hot side (bottom)Last edited by plAythiNG; 26-03-16, 06:11 PM.

Comment

-

Nice read Alex. Heaps of digging around you've had to do.Originally posted by plAythiNG View PostPicking up on the oil cooler install, as mentioned from the very beginning, the oil temp sensor is the only PITA part of the entire install. Issues I experienced were;

-where to found sensor

-typical places to mount said sensor gave me mixed results - volatility in temp readings in street conditions

-difficulty in mixing different region parts to work together, IE defi sensors utilise BSPT/PT(British) whereas Earls being American all use NPT etc

I even bought a spacer fitting by Trust/Greddy, and that was a failure where the threads were too lose, and didnt screw in enough on the defi (female side) as well as on the male side too....

Since I already have the part, and it is indeed useless to me, Im going to get both ends trimmed off to see fitment.... I'll get pics of this later on, as I lost all my phone photoes...

Anyways, I thought I do this post to anyone reading to go for the Greddy sandwich plate... As I mentioned initially, it is the perfect design for where the thermostat is located, offers two ports for sensors. It's only downfall is the low operating thermostat, and if I had to be picky, it could use a thicker O ring like the mocal. That is where the Mocal excels, it's O ring is 4, maybe 5 times larger than the Greddy, an it does have a high temp thermostat that closes at 93c!

Saru, another S2000 owner here has installed the Trust Oil Cooler kit and is scratching his head why the oil temp readings are mysteriously low.

I've already explained in a previous post how the Mocal sadnwich plate operates, but I'd like to explain a key difference is how each thermostat moves to direct oil...

Firstly the Mocal sandwich plate, oil leaves the block and either falls into the oil cooler hose, or through the other side that goes into the oil filter and then directly back ino the engine block via the center hole... Yeah Mocal Technician, there really is just 5% flow of oil when below 93c aye....

Now the Greddy sandwich plate. Lets see some pictures first!

This is the side shot of the sandwich plate. Left side is where oil filter screws. Right side faces the engine block.

This side mates to the engine block. The key difference of design starts here. See here, there is only one place for the oil to go towards, and that is towards the oil cooler hose. Even on this pic, you can see a small hole where you can see my yellow skin. This is where the oil flows through when below 70C, as well as oil going towards the cooler.

This is the other side, the side where the oil filter faces. Here is a better shot of that hole where oil flows through when below 70C

So I also tested the thermostat and what happens!

Here we are over 70C, and the thermostat begins to move. It moves to the left, thus closing and block off all flow of oil to the hole. The oil can now only be directed to the oil cooler hose, and thus through the cooler to be cooled.

temps are now over 80C, and you can see the thermostat has completely moved over and now 100% flow of oil going through to the cooler!

I did record a couple vids of the thermostat moving but they're taking ages to upload....

Anyways the important shit is above... SO looking at all that. Referring to this pic again

The hose at the bottom collects HOT oil from the engine, goes to the cooler, then the cooler disperses the now cooled oil fmor the top hose and back into the sandwich plate (top) Looking at Saru's pic here

His temp sensor is giving readings on what the temp is AFTER cooler, hence the reason why his defi ZD shows lower than expected reading.

There are many arguments to which side you want to run your temp sensor. In an ideal world where it is easy to setup and cost effective, you'd want to run a temp sensor before and after! But due to constraints in life, The oil temp sensor I would personally put it on the hot side (bottom)

With oil, I'd agree with the temp sensor on the hot side. Ideally you want to get it at the hottest part (as it leaves the engine). You are always most interested in how hot the oil in the engine as that's what affects lubrication.Wakefield: EG B18CR - R888 - 1.09.9

Eastern Creek: DC5R - RE001/ER300 - 2.00.8

Winton: DC5R - RE001 - 1.45.9

Comment

-

Finally oil cooler is installed! what a long journey just on that, but glad it all has worked out well in the end!

So today I used some thread sealant and tightened the fittings and defi sensors onto the greddy sandwich plate. Bolted the plate to the block, installed the lines, and went to tighten down the oil filter! First problem encountered.. Tested the bolt onto honda oem filters, and it screwed on perfect fine, but when I installed it to the block and tried to tighten down the filter, it was mate, turn a few threads, and as I went to tighten it, it could come off... confusing, but removed this bolt, and used my old Mocal one. its a lil taller on both male and female ends, and got the filter on no problems!

I then put in 5.5L of oil and took it for a short drive. rough estimation here, but street driving with no vtec, the oil reaches a milestone of 70c approximately 4-5 minutes longer than no cooler. I also did a few redlines of vtec for around 3-5 minutes, and a max oil temp recorded was 94c! pretty happy about that so far. I am still yet to do any tests with more controlled variables, but that'll come eventually!

I also test fitted my block off plate, thats simply attached via a wing nut and wing bolt, for ease of remove and reinstall! have hit with this some rust proof in black, and will aply some rubber stripping to minimum any vibrations also.

I also installed oil temp sensor before and after oil cooler to see comparisons. Will write up some more whilst im uploading the images!

Comment

Comment