G'day Honda mates! Felix invited me to start a build thread so thanks for having me at ClubITR. I've been working on this City Turbo with a friend for about six weeks now. We've made a fair bit of progress so I'll post everything we've done so far in a few sections then do my best to keep this thread up to date.

We originally found it on Gumtree. We weren't (and still aren't) exactly sure what to do with it (rego/track/sell/other) but it was too good to pass up. I finished a motorbike build recently and had a hankering to work on something else. Plus the guy I'm building it with has a Motorcompo on the way from Japan so we had to pair them up. I'll start from the top.

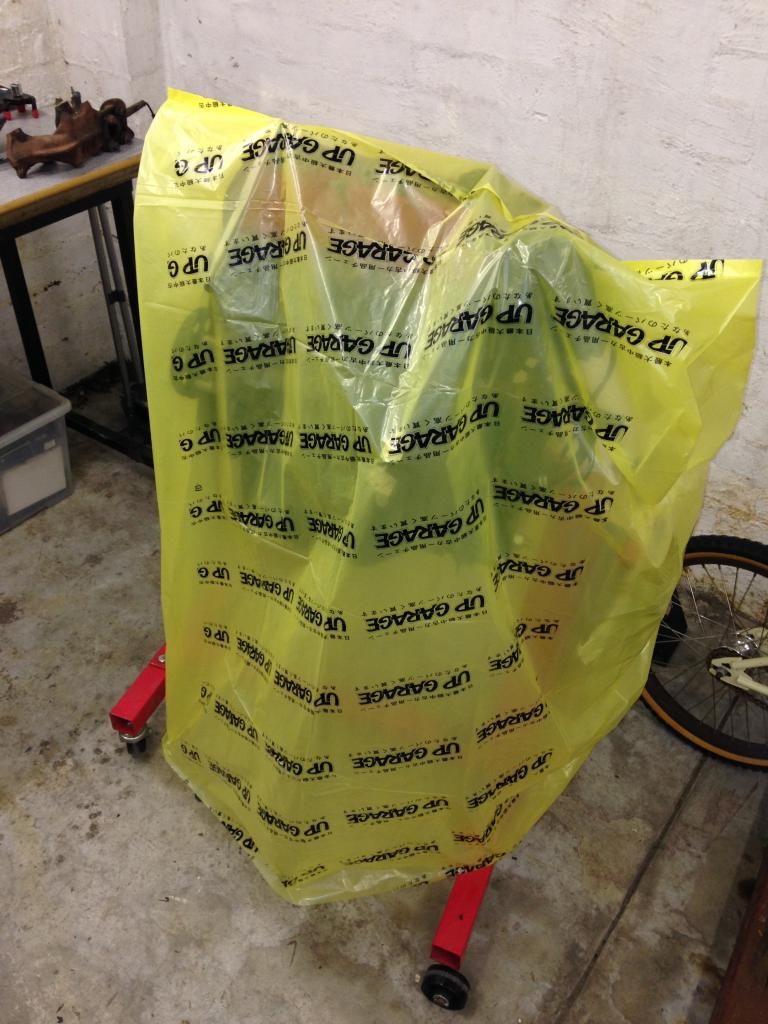

All moved in to its new home for the next little while.

It was cheap because:

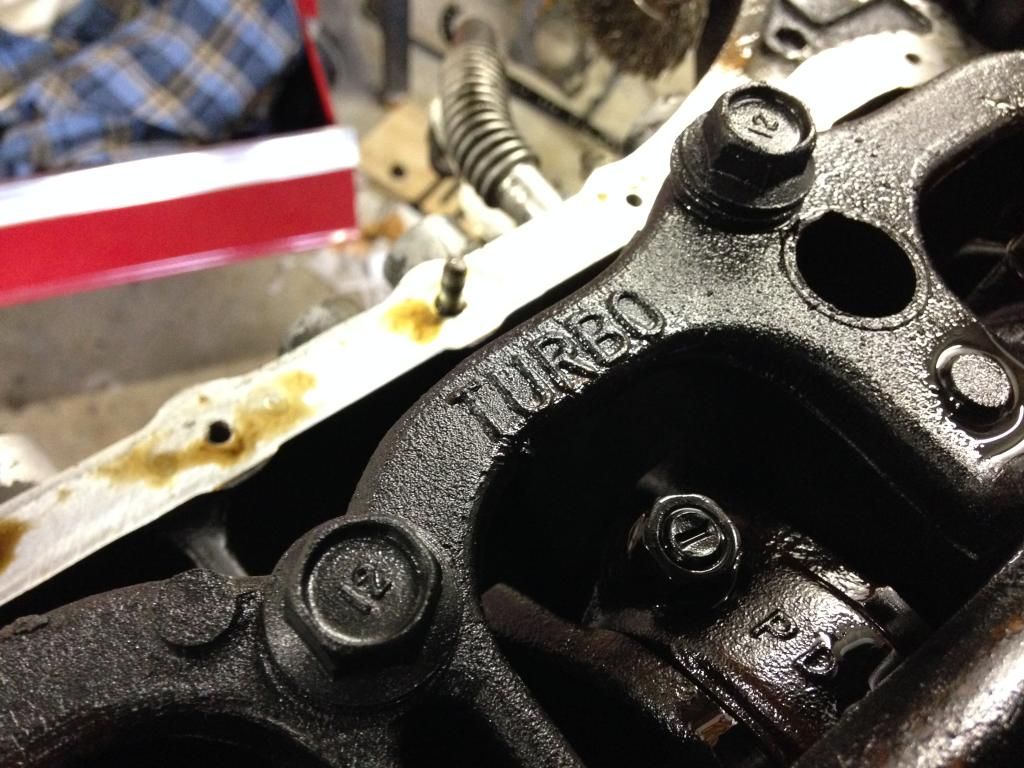

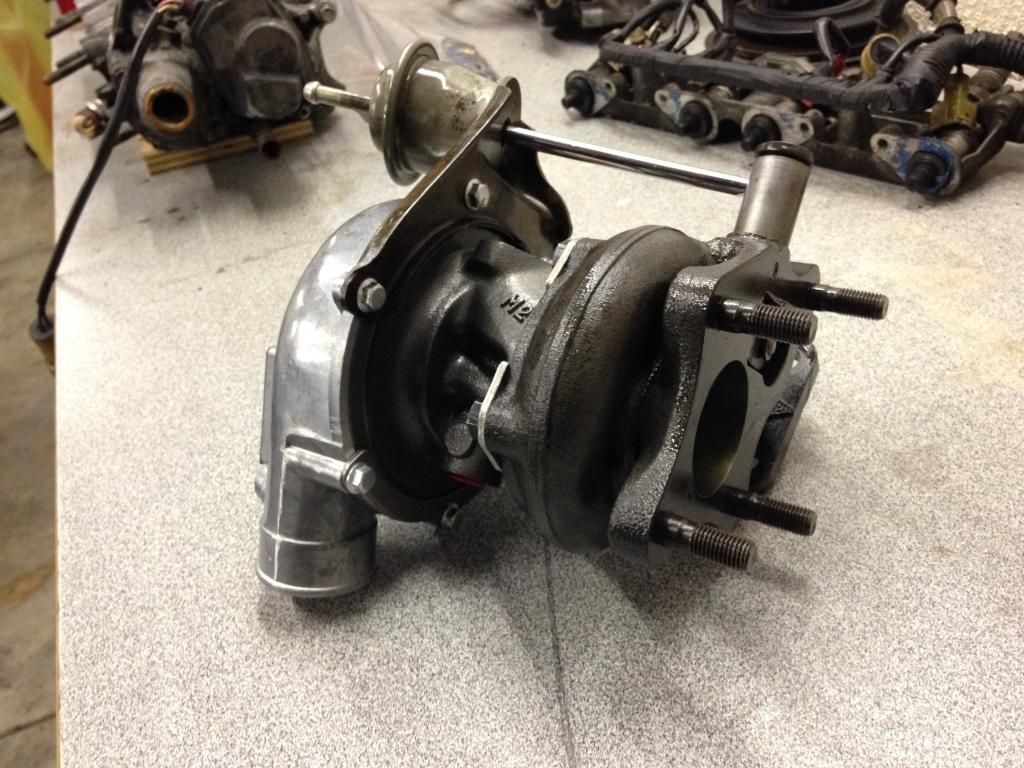

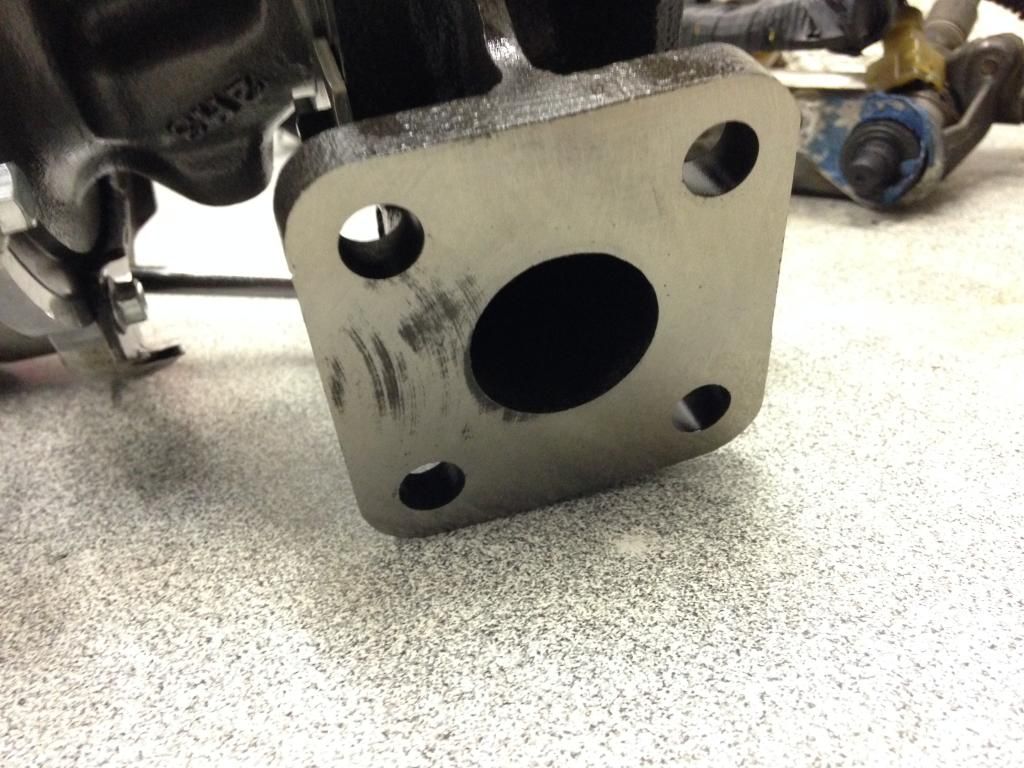

Not running. Came with a very dead turbo, no fuel pump and lots of holes where parts should be. Thankfully we also got a boot full of bits to be assembled including a head rebuilt kit and a turbo diesel Pajero turbo which was supposed to be an 'easy replacement' according to the last owner. Not likely.

Like I said, we got straight into it.

Boot o' bits. Basically a bunch of driveshafts, turbo diesel Pajero turbo and other odds and ends.

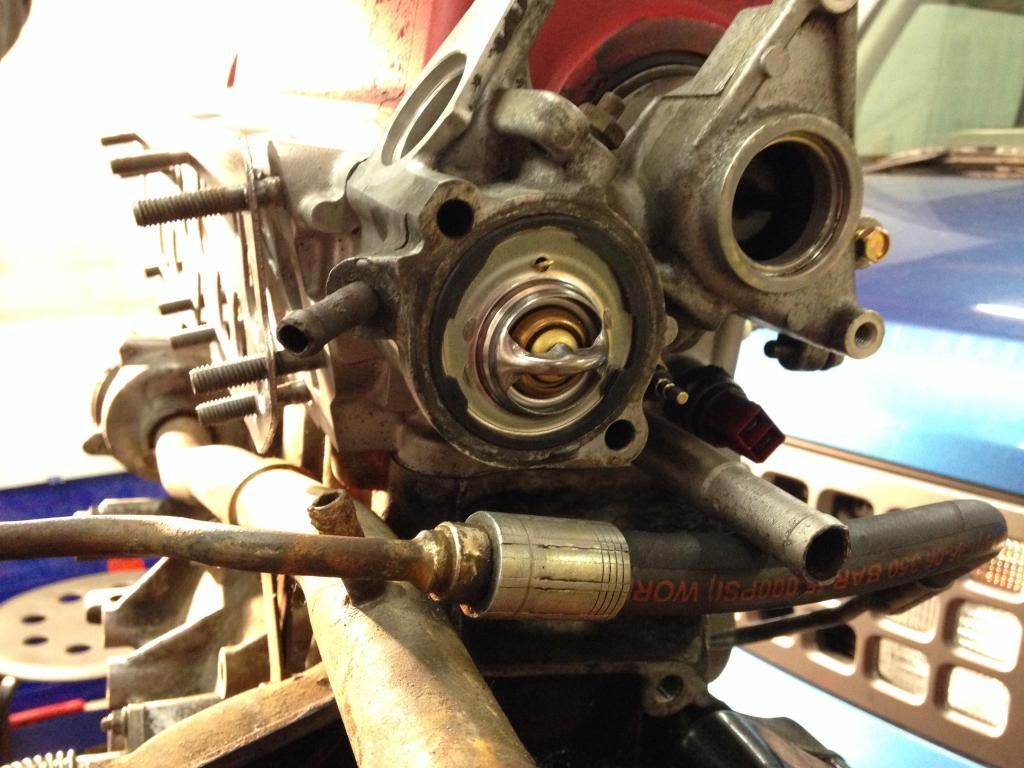

More spares for the build. Looks like these radiators won't work out so that's on our list of things to source. The top hose fitting has broken off the original and the non-turbo City radiator doesn't look like it'll fit.

Derp.

The whole car is covered in filthy fingerprints and dirt. For the most part the body is in decent condition. A proper wash should bring it up to a reasonable state.

We have no idea what happened to the original rear bumper but the car came with a replacement from a convertible. City drop tops have the same wide body guards as the Turbo II but the bumpers are black plastic instead of body colour. We'll paint it down the track.

This is by far the thing I hate the most about this car. It seems no amount of Rost Off will free up the grub screws holding it on. Angle grinder up next.

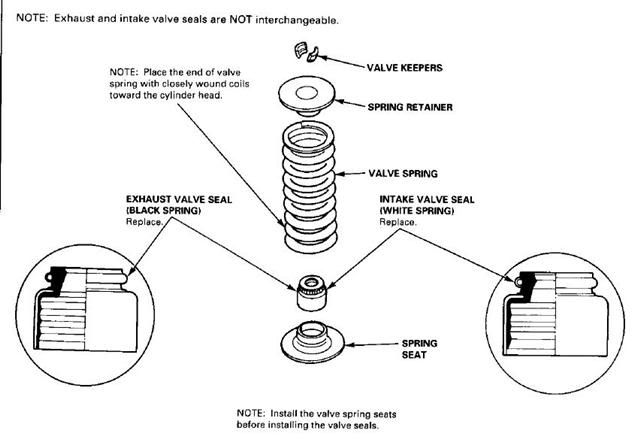

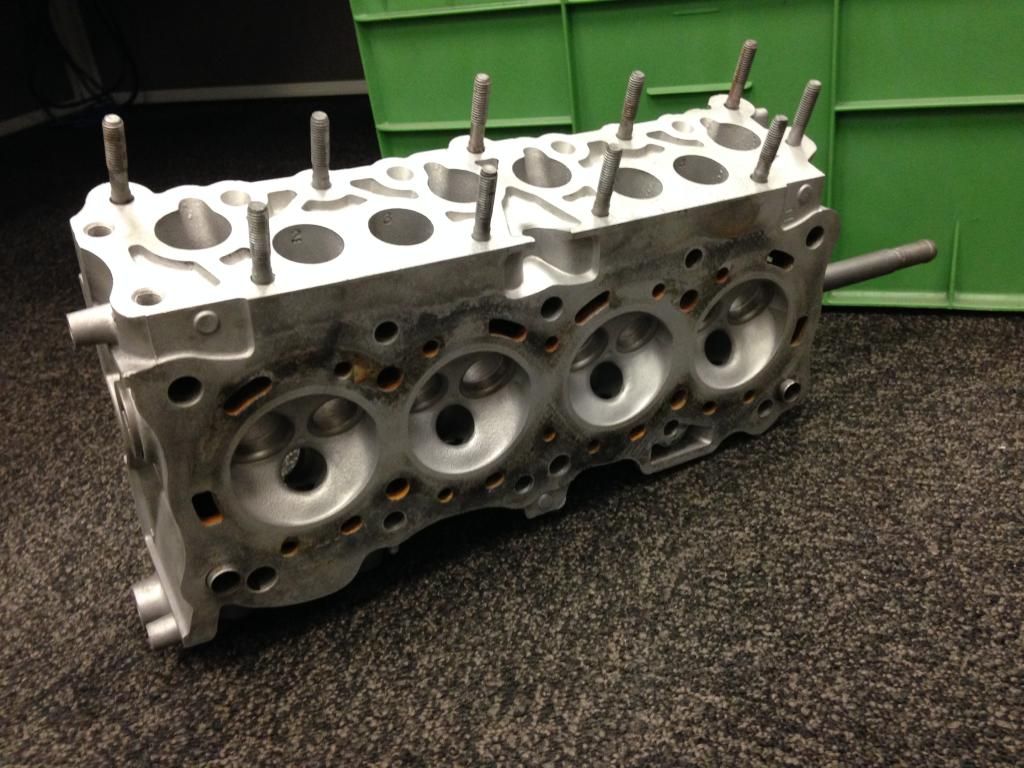

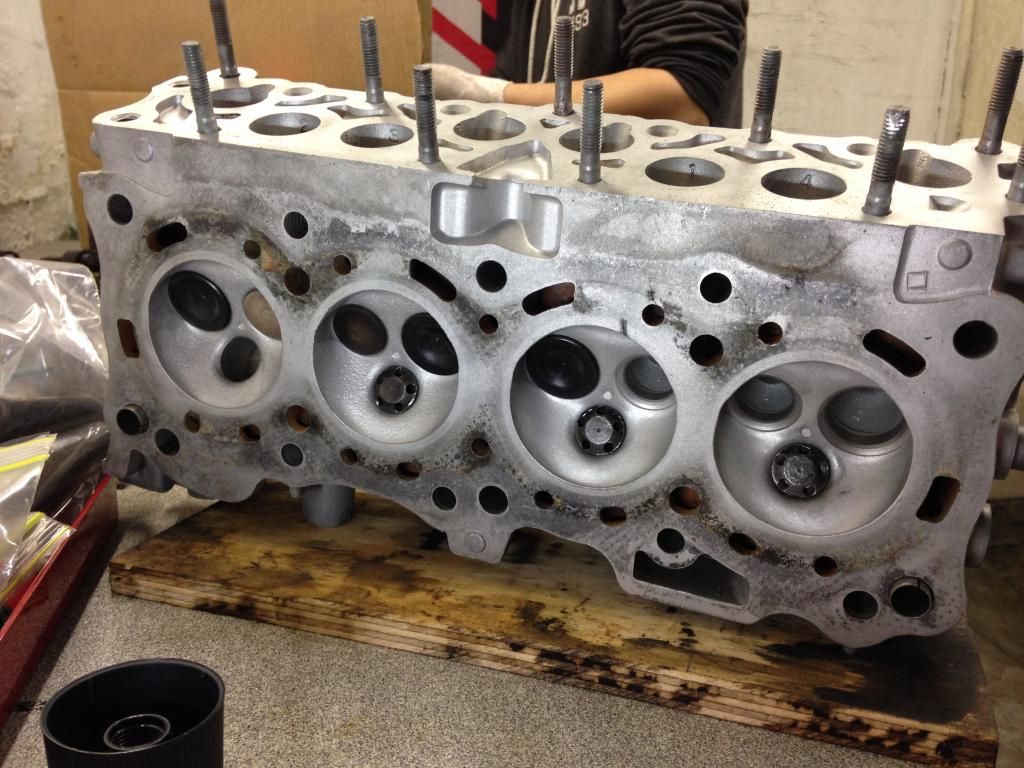

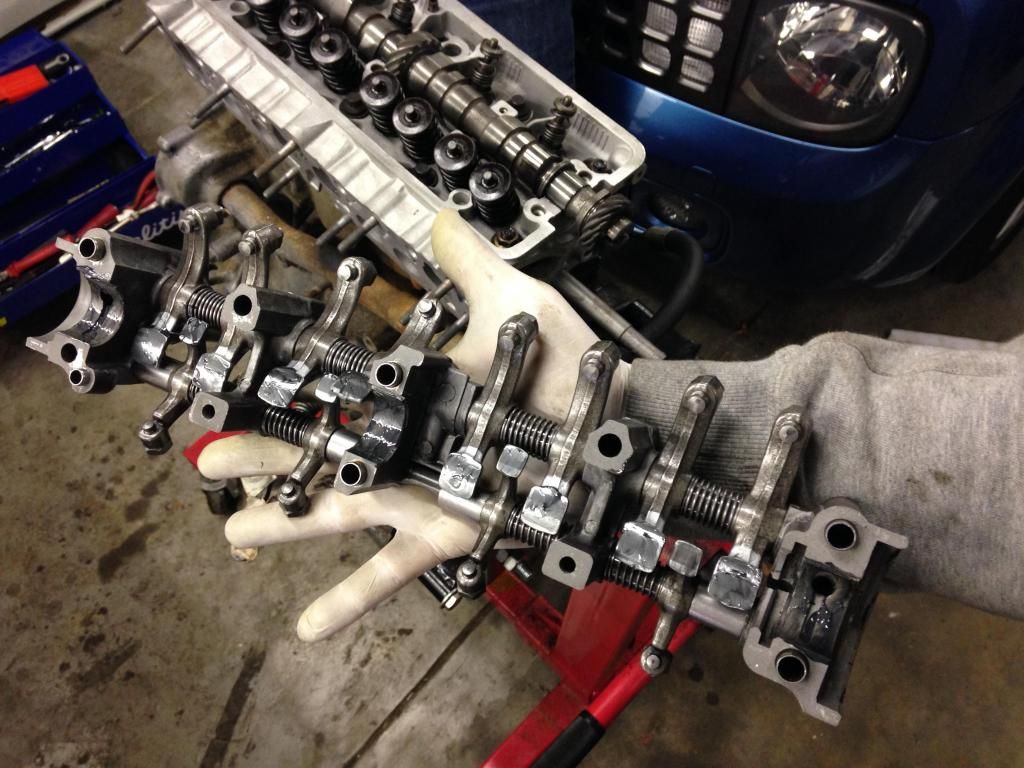

We wanted to yank the motor out straight away for a proper look at the exhaust manifold and to get started on the freshen up. The car came with a complete gasket and seal kit for the top end so we'll be making the most of that.

Front bumper and grill removed for heaps of access. We don't want any air con gear in the car so the condenser came out and went in the bin. Everything disconnected and labelled and rad support removed.

Engine crane time.

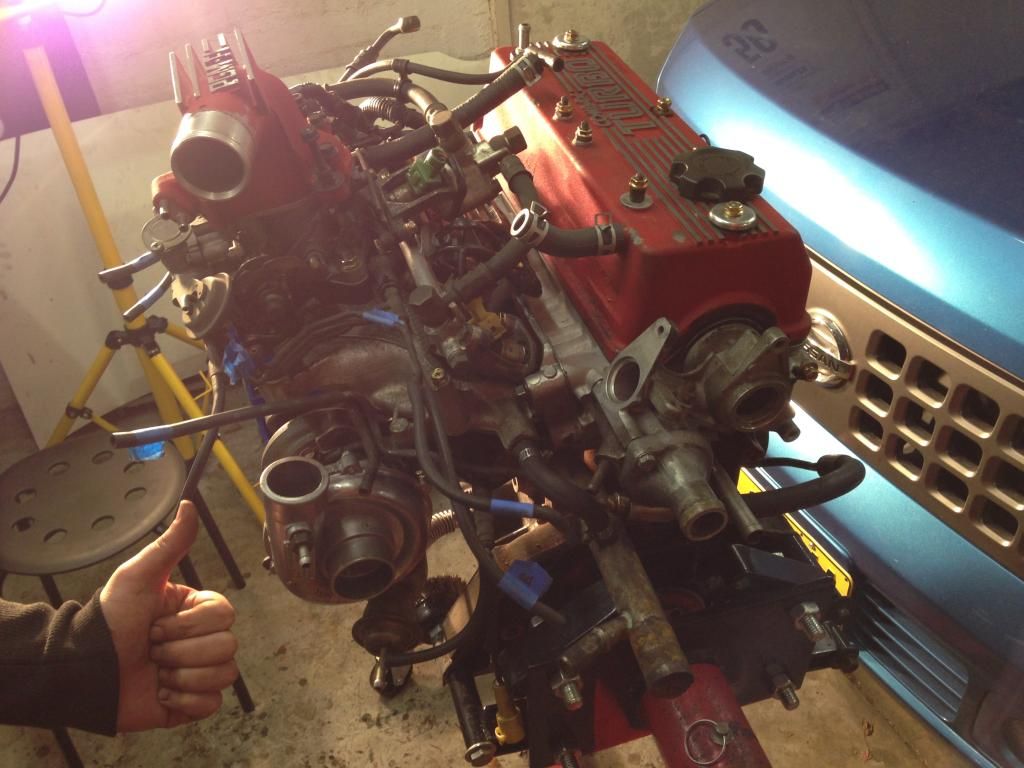

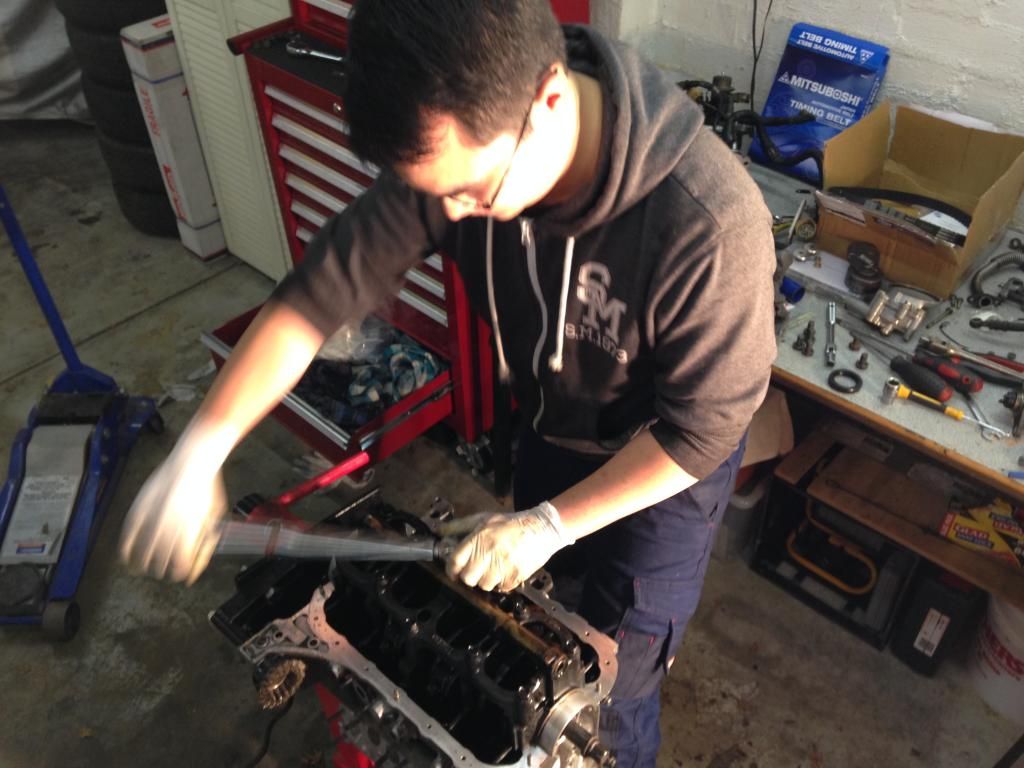

Winners are grinners. It took us three hours from kick off to engine out. Pretty stoked with that.

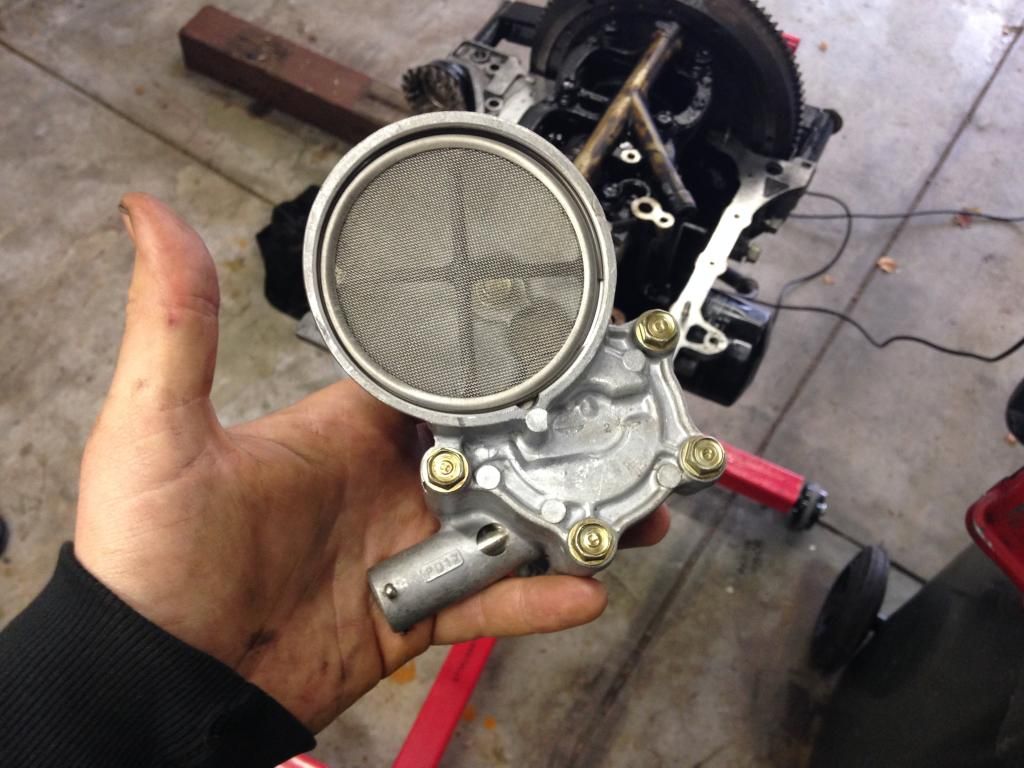

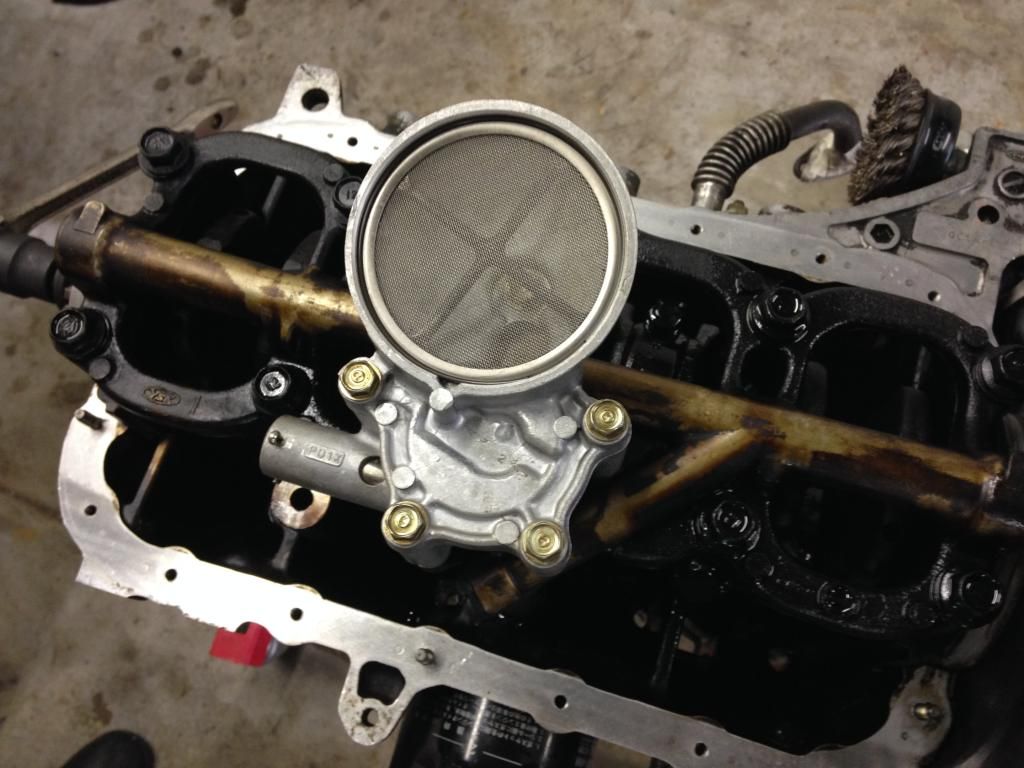

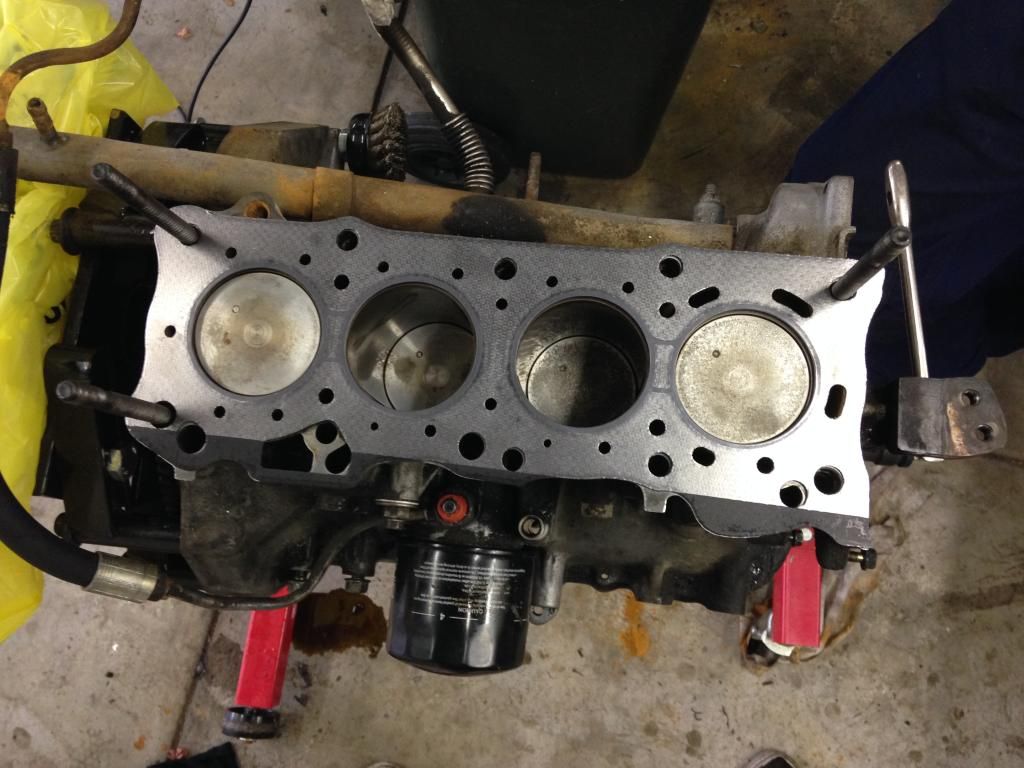

We dropped the oil out and got the engine onto a stand so we can work on it easily.

Dirty engine bay is dirty.

Degreaser and Karcher tiem.

Fair bit better. Both of us get pretty OCD at times, but this is definitely not going to be a concours rebuild. The body is a little rough so it doesn't need to be perfect.

A friend brought over a set of CF-48s for us to use while we've got the City. May or may not end up on the car.

Loving having this funny car in the garage. So good to be working on a new project.

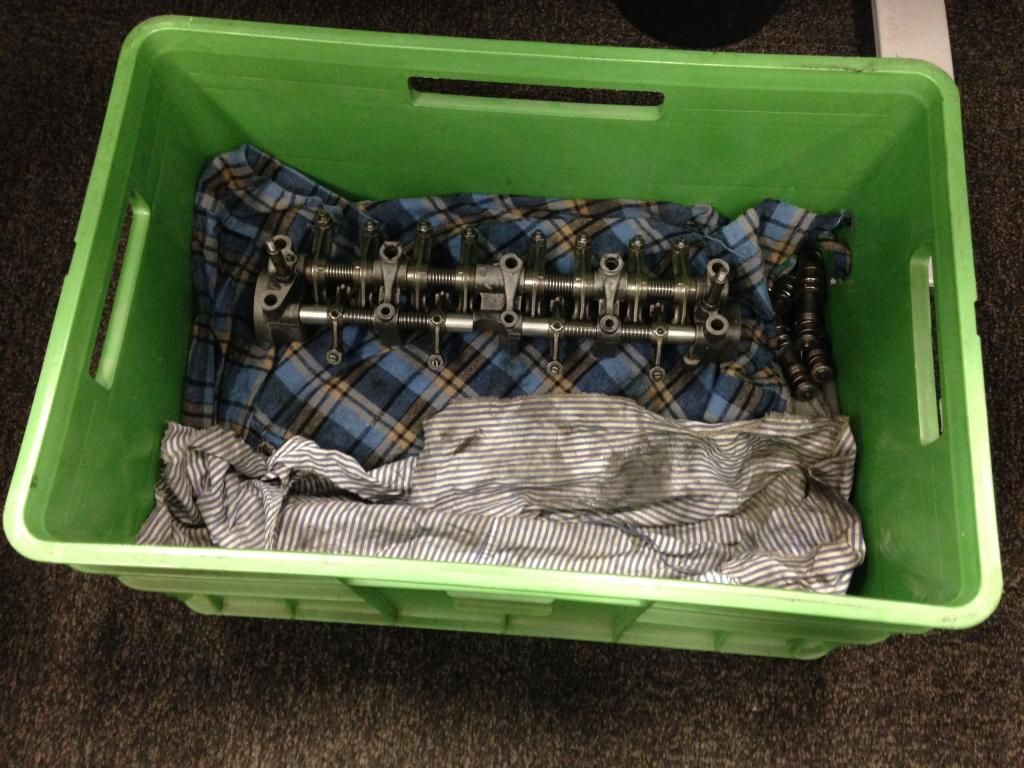

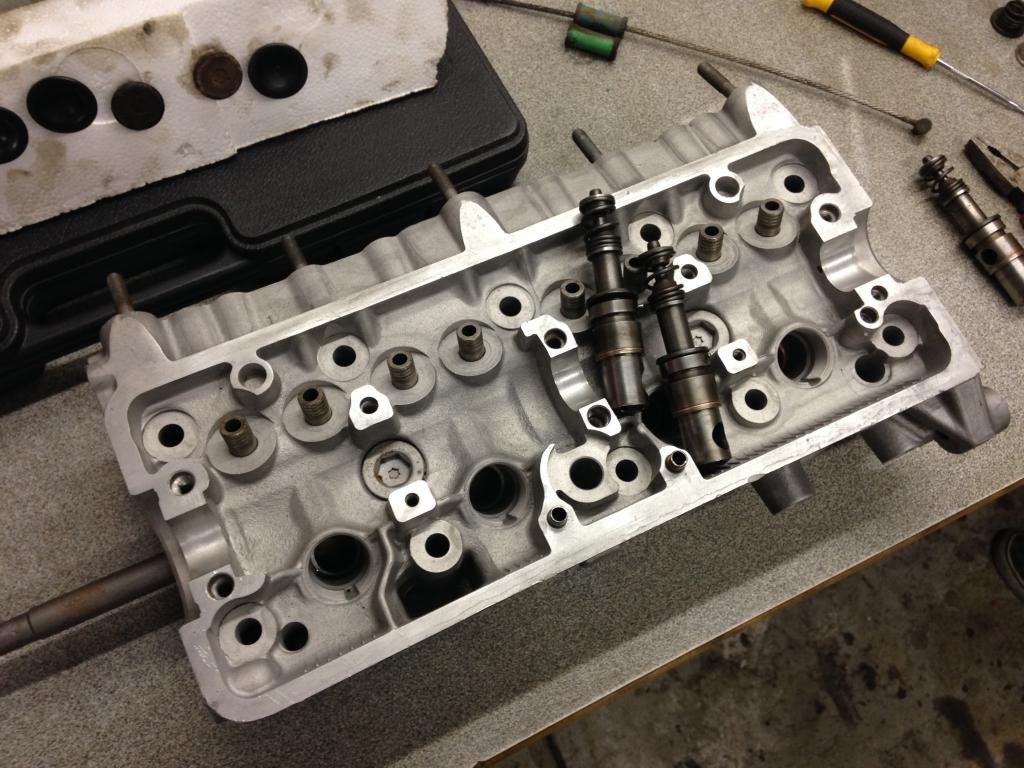

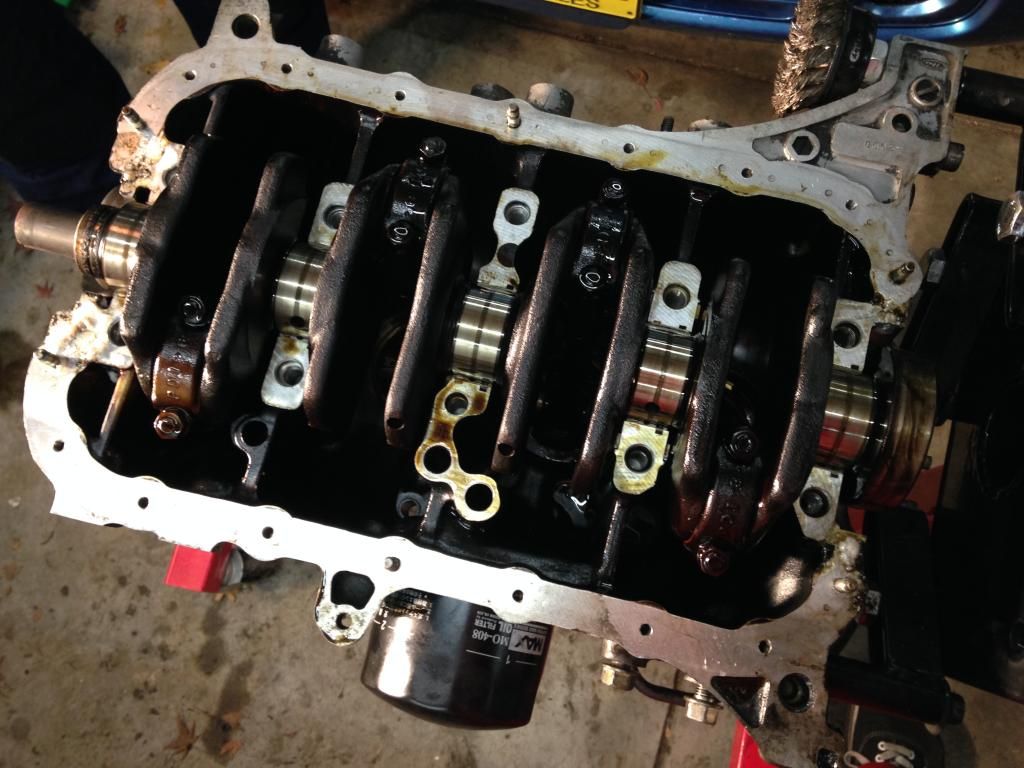

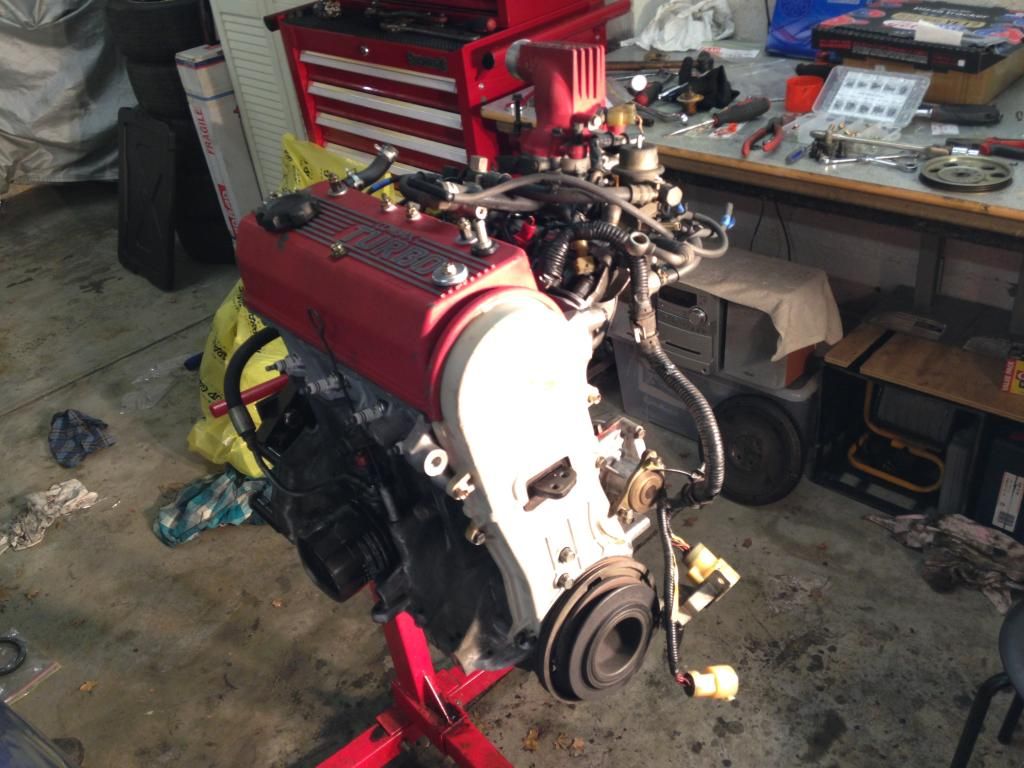

I'd never had an engine stand at home before but I'll never go back now! So good to have it at bench height. The motor looks to be in pretty good order. We're told that it had good, even compression across all cylinders but there's a lot of caked on carbon under the valve cover. We don't want to commit to a total nut and bolt overhaul so we'll just have to see how it goes.

The A/C stuff we've binned so far. The car didn't have a compressor in it when we got it. Removed a few kilos there.

Fairly sure this is the original clutch but it's good to go back in. Pressure plate and flywheel look fine too. I should also mention that this is a low budget build. We're trying not to get into it for more than the car will be worth when it's finished.

Little five-speed 'box all looks fine. Throwout bearing needs to be replaced but that's it. City Turbo stuff isn't exactly dime a dozen but we've found stuff pretty easily in New Zealand.

We originally found it on Gumtree. We weren't (and still aren't) exactly sure what to do with it (rego/track/sell/other) but it was too good to pass up. I finished a motorbike build recently and had a hankering to work on something else. Plus the guy I'm building it with has a Motorcompo on the way from Japan so we had to pair them up. I'll start from the top.

All moved in to its new home for the next little while.

It was cheap because:

Not running. Came with a very dead turbo, no fuel pump and lots of holes where parts should be. Thankfully we also got a boot full of bits to be assembled including a head rebuilt kit and a turbo diesel Pajero turbo which was supposed to be an 'easy replacement' according to the last owner. Not likely.

Like I said, we got straight into it.

Boot o' bits. Basically a bunch of driveshafts, turbo diesel Pajero turbo and other odds and ends.

More spares for the build. Looks like these radiators won't work out so that's on our list of things to source. The top hose fitting has broken off the original and the non-turbo City radiator doesn't look like it'll fit.

Derp.

The whole car is covered in filthy fingerprints and dirt. For the most part the body is in decent condition. A proper wash should bring it up to a reasonable state.

We have no idea what happened to the original rear bumper but the car came with a replacement from a convertible. City drop tops have the same wide body guards as the Turbo II but the bumpers are black plastic instead of body colour. We'll paint it down the track.

This is by far the thing I hate the most about this car. It seems no amount of Rost Off will free up the grub screws holding it on. Angle grinder up next.

We wanted to yank the motor out straight away for a proper look at the exhaust manifold and to get started on the freshen up. The car came with a complete gasket and seal kit for the top end so we'll be making the most of that.

Front bumper and grill removed for heaps of access. We don't want any air con gear in the car so the condenser came out and went in the bin. Everything disconnected and labelled and rad support removed.

Engine crane time.

Winners are grinners. It took us three hours from kick off to engine out. Pretty stoked with that.

We dropped the oil out and got the engine onto a stand so we can work on it easily.

Dirty engine bay is dirty.

Degreaser and Karcher tiem.

Fair bit better. Both of us get pretty OCD at times, but this is definitely not going to be a concours rebuild. The body is a little rough so it doesn't need to be perfect.

A friend brought over a set of CF-48s for us to use while we've got the City. May or may not end up on the car.

Loving having this funny car in the garage. So good to be working on a new project.

I'd never had an engine stand at home before but I'll never go back now! So good to have it at bench height. The motor looks to be in pretty good order. We're told that it had good, even compression across all cylinders but there's a lot of caked on carbon under the valve cover. We don't want to commit to a total nut and bolt overhaul so we'll just have to see how it goes.

The A/C stuff we've binned so far. The car didn't have a compressor in it when we got it. Removed a few kilos there.

Fairly sure this is the original clutch but it's good to go back in. Pressure plate and flywheel look fine too. I should also mention that this is a low budget build. We're trying not to get into it for more than the car will be worth when it's finished.

Little five-speed 'box all looks fine. Throwout bearing needs to be replaced but that's it. City Turbo stuff isn't exactly dime a dozen but we've found stuff pretty easily in New Zealand.

Comment