Car Prep and maintenance.

Previous update had me discovering a leaky brake/clutch master cylinder and totally destroying my rear brake pads.

A mate had a wrecked S2000 with fresh looking master cylinders and offered me to swipe them, and so I did. Cheers!

Leaky Clutch Master Cylinder – 159K KM

Truthfully this is due to my negligence of not regularly changing the clutch fluid.

Fresher Clutch Master Cylinder

No leak, with a sludge of grease behind the cylinder. Install was straight forward, bolt in and bleed the clutch line with ATE Superblue fluid.

Brake Master Cylinder Replacement.

Old one was removed and clearly has signs of internal leakage with corrosion occurring on the BMC and booster.

Fresher BMC with no sign of leakage.

As my booster was quite corroded, I opted to take the booster also from my mates wreck. Thanks again!

Here is the replaced BMC and booster. Bled the whole brake system again with ATE Blue fluid.

Suspension Inspection.

Last track day I was complaining of some front end push at Winton, particular at the sweeper. As I thought the suspension was maxed out under compression. The remedy was to look into upgrading the spring rates. Bit of a band-aid fix.

I then made the discovery that the spring rates on the Tein Monoflex set I have were actually 12/10kg according to the spring part number. Not 10-8kg as I was advised by the previous owner 5 years ago, haha. I measured the spring length anyway just in case that I wanted to purchase new springs and inspected and cleaned the coil over.

I then made another discovery that the front lower control arm bushings were totally ruined, particularly the front compliance bushing, which may explain the front end slop. A deteriorated bushing definitely has a big influence on the wheel alignment which is possibly causing accelerated front tyre wear and the front end push. Replacing this is a good idea.

The front tyres were showing accelerated inner wear, which is odd as I’ve been running these alignment specs for a long time and I’ve never seen camber wear like this. I opted to get the tyres flipped to maximise these tyres life.

Rear brake pads were pretty much dead and on the backing plate. These were replaced with PMU B-Specs, which were my spares I had laying around.

Haltech CAN Art Gauge.

Finally I have a method of viewing my temperatures of some of the cars vitals. I liked this gauge as it is low key and it is the one gauge to view it all, it enables me to view every parameter from the ECU. IAT, water, oil, knock, boost, injector duty, etc. It is configurable via a phone app and displays 4 parameters at a time with the ability to configure over 8 different pages of data.

I haven’t bothered to properly mount it yet as it was getting close to a track day I wanted to attend. So I opted for the trusty Repco duct tape. Solid job.

Questionable modifications to the S2000 - JDM Rear crash bar – Weight Reduction.

Replaced the rear crash bar with the JDM version. JDM = 1.8KG, AUDM = 5.4KG

3CLab Carbon Cooling Plate

It looks cool, it covers the gaping hole at the front while supposedly providing better airflow to the radiator.

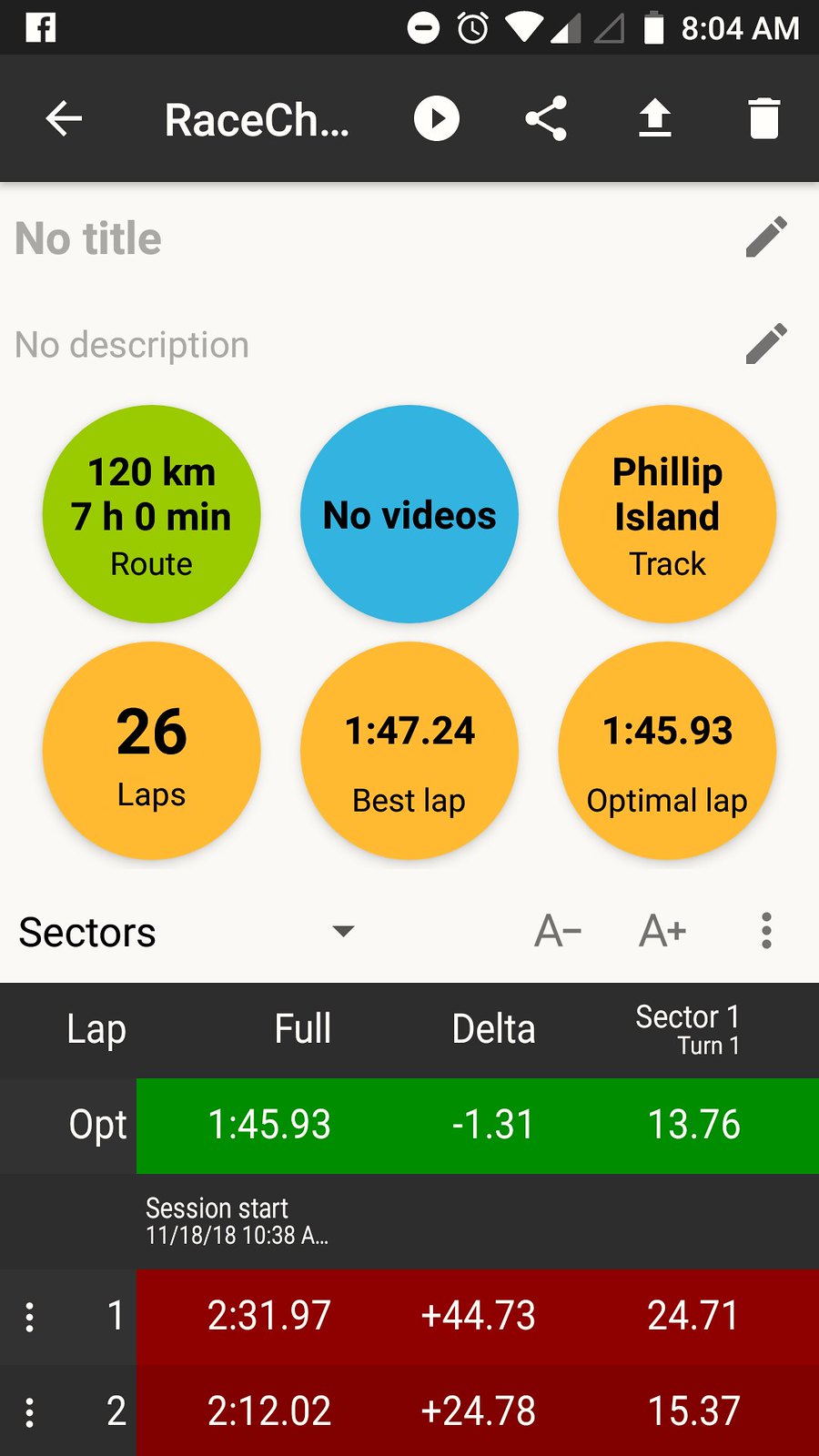

With everything completed, it is ready for another track day. Next stop Phillip Island GP Circuit.

Previous update had me discovering a leaky brake/clutch master cylinder and totally destroying my rear brake pads.

A mate had a wrecked S2000 with fresh looking master cylinders and offered me to swipe them, and so I did. Cheers!

Leaky Clutch Master Cylinder – 159K KM

Truthfully this is due to my negligence of not regularly changing the clutch fluid.

Fresher Clutch Master Cylinder

No leak, with a sludge of grease behind the cylinder. Install was straight forward, bolt in and bleed the clutch line with ATE Superblue fluid.

Brake Master Cylinder Replacement.

Old one was removed and clearly has signs of internal leakage with corrosion occurring on the BMC and booster.

Fresher BMC with no sign of leakage.

As my booster was quite corroded, I opted to take the booster also from my mates wreck. Thanks again!

Here is the replaced BMC and booster. Bled the whole brake system again with ATE Blue fluid.

Suspension Inspection.

Last track day I was complaining of some front end push at Winton, particular at the sweeper. As I thought the suspension was maxed out under compression. The remedy was to look into upgrading the spring rates. Bit of a band-aid fix.

I then made the discovery that the spring rates on the Tein Monoflex set I have were actually 12/10kg according to the spring part number. Not 10-8kg as I was advised by the previous owner 5 years ago, haha. I measured the spring length anyway just in case that I wanted to purchase new springs and inspected and cleaned the coil over.

I then made another discovery that the front lower control arm bushings were totally ruined, particularly the front compliance bushing, which may explain the front end slop. A deteriorated bushing definitely has a big influence on the wheel alignment which is possibly causing accelerated front tyre wear and the front end push. Replacing this is a good idea.

The front tyres were showing accelerated inner wear, which is odd as I’ve been running these alignment specs for a long time and I’ve never seen camber wear like this. I opted to get the tyres flipped to maximise these tyres life.

Rear brake pads were pretty much dead and on the backing plate. These were replaced with PMU B-Specs, which were my spares I had laying around.

Haltech CAN Art Gauge.

Finally I have a method of viewing my temperatures of some of the cars vitals. I liked this gauge as it is low key and it is the one gauge to view it all, it enables me to view every parameter from the ECU. IAT, water, oil, knock, boost, injector duty, etc. It is configurable via a phone app and displays 4 parameters at a time with the ability to configure over 8 different pages of data.

I haven’t bothered to properly mount it yet as it was getting close to a track day I wanted to attend. So I opted for the trusty Repco duct tape. Solid job.

Questionable modifications to the S2000 - JDM Rear crash bar – Weight Reduction.

Replaced the rear crash bar with the JDM version. JDM = 1.8KG, AUDM = 5.4KG

3CLab Carbon Cooling Plate

It looks cool, it covers the gaping hole at the front while supposedly providing better airflow to the radiator.

With everything completed, it is ready for another track day. Next stop Phillip Island GP Circuit.

Comment