Nice update! Car is progressing nicely

Announcement

Collapse

No announcement yet.

Civic Sedan Build - JTCC Inspired

Collapse

X

-

Nice of you to say so, when are we going to see some EG updates huh?Originally posted by dnapol View PostNice update! Car is progressing nicelyHoned - WEB: https://honeddevelopments.com/ FB: https://www.facebook.com/honeddevelopments

Comment

-

So just prior to the Sandown event I replaced the original oem radiator cap with a Spoon 1.3 bar unit,

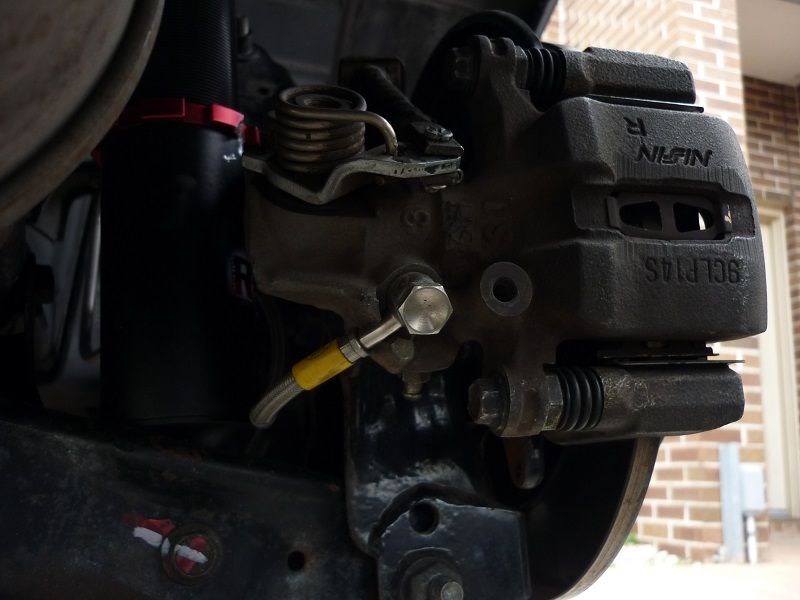

and at the same time I swapped out the brake lines with a HEL braided line kit. The original rubber lines were looking a bit tired and i didn't want to risk a brake line failure given the reasonable price to replace them.

A couple of weeks ago I went up to Winton to spectate while a friend was running his car, after each session I would meet him in the pits and ask him how his car felt and after a few sessions I noticed that straight out of the driver's seat he would only give short, not very specific answers, things like "yeah alright" or "the car felt good" At the time i thought he was just not very good at retaining specifics about what the car was doing and relaying them to his team but

Then at Sandown the other week my friend Tom was asking me the same things after each session, and I found myself only giving minimal answers. I realised that, for me at least, the track session is pretty taxing, and when I first step out of the car my mind is still spinning, so trying to give any feedback about what the car is doing is pretty hard.

I'm sure those stories of Senna asking for another 2 psi in his front right tyre as soon as he stepped out of the car are true but it's a different story when you're still trying to learn tracks let alone working out what the car wants.

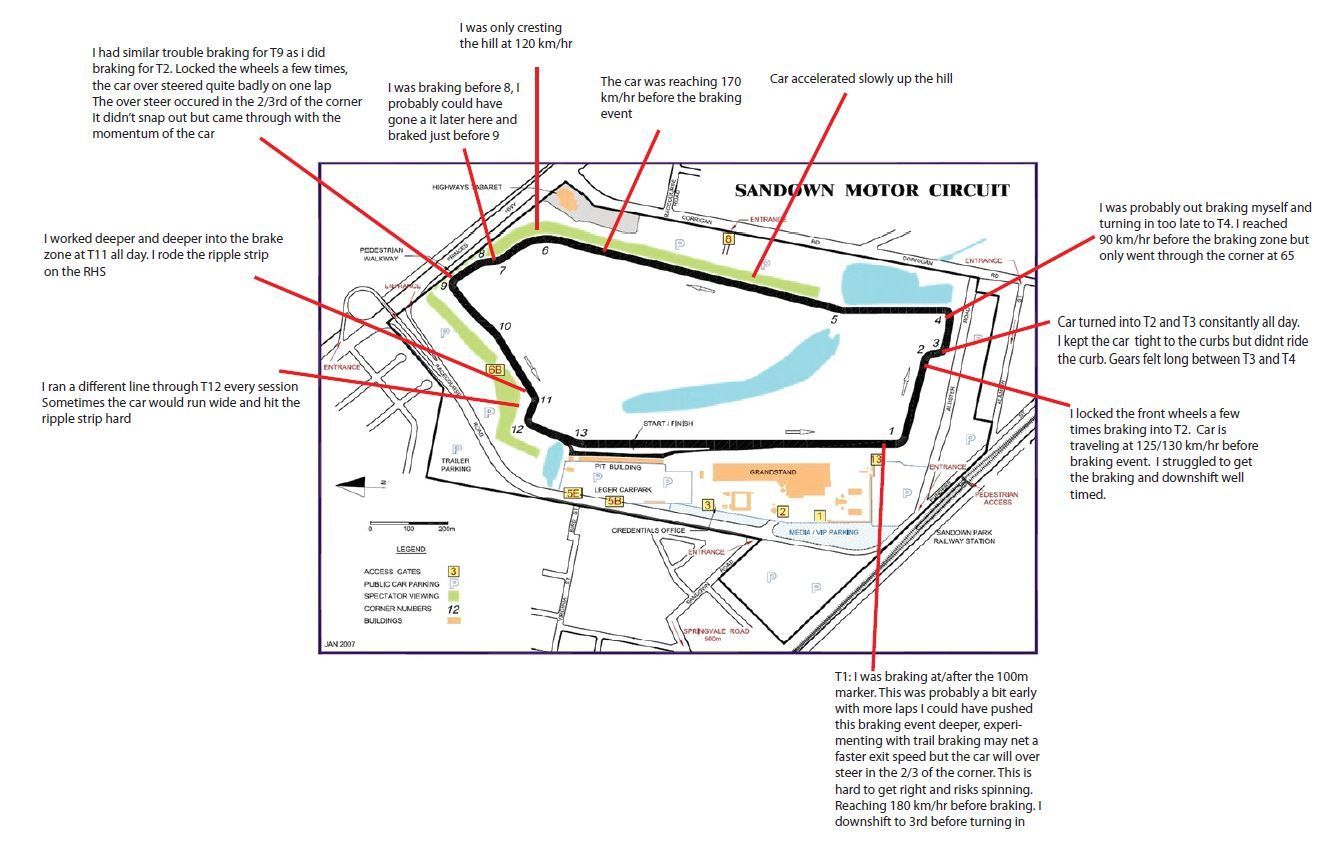

So my strategy is to sit down the day after the event and annotate a track map with my thoughts, here's my feedback from Sandown

Looking at my notes, I mention the brakes locking or out braking myself a few times so I concluded that something is not quite right with my brake set up

My brake set up at Sandown:

No ABS

1" Master Cylinder + Abs booster

280mm front rotor + ITR caliper + Hawk blue pads

260mm rear rotor + Vti-r caliper + bendix pads (repco)

braided lines

The symptoms I described sounded like I had too much front bias and since dc2r's come with 260mm rear brakes i thought that a good place to start would be to upgrade the rear brakes to 260mm

So i brought a set of DC2r caliper brackets thinking that the type R and Vtir rear caliper would be the same, turns out they arn't and dc2r has it's own specific rear caliper. I didn't have time to source a set of dc2r calipers so I went to the pick a part and found a set of prelude rear calipers which will work, but have the bleed nipple in the wrong spot.

After running around doing all this a street test debunked my theory and although the car seemed a little better it still locked its front brakes pretty easily.

When I street tested the car I only had the small 195/50/15 tyres on and so it was conceivable that with the AD08r's (and 17's) on the car would be alright.

Since I had another track day booked in for the following weekend I didn't have any other option than to run with it.Honed - WEB: https://honeddevelopments.com/ FB: https://www.facebook.com/honeddevelopments

Comment

-

I drove the car up to Benalla on Saturday afternoon in preparation for the exe track day at Winton the following day.

I made the fender spacers adjustable so I can convert the car back to a more subtle "road" spec to drive on the highway.

I put the standard seat back in and fit the 15" wheels, it's still loud and bumpy but its survivable

It's funny to think back to when I was younger and I would look at full on track cars and think "yeah I'd daily drive that!" I had no idea haha

So track day morning comes, the weather is a little cold but at least its dry. After a quick meet and greet I get myself set up with a spot in the pits and we go through scrutineering and driver briefing

I got put in group C so i was in the third group of cars out on track.

Group A go out and from the pits we can see a few cars go off the track. When the drivers come in they were all reporting a pretty slippery track.

Group B go out and about mid session there was a pretty big incident, a car went into the wall and that slowed everything up for a while.

When my group finally got called I was one of the first cars into the staging area and ended up being the first car out on track

I had a passenger with me and we did a few laps to feel out the track and then on about lap 5 or 6 I tried to go just a bit quicker through the sweeper and the rear end came around on me.

I couldn't save it and the car looped around and went backwards over this nasty ripple strip. BANG!

After I apologized to my passenger I drove back onto the track but realised immediately something wasn't right .

I thought maybe we had de-beaded a tyre and drove the car cautiously back to the pits

When we got back to the pits we jumped out of the car to survey the damage, we check the tyres and they seemed to be alright but then as I stepped back i noticed one of the rear wheels had a bit more camber than it should have

Yep snapped the right rear camber arm! those of you who know will probably take one look at that and see it is a cheap ebay camber arm made from aluminium. It serves me right, i knew I should have replaced it!

That wasn't the entirety of the damage through, the front left rim took a hammering as well

That pretty much ended my day. I was lucky enough to get a ride in an Evo which was an eye opening experience! It was great to experience what 10 seconds a lap faster than what I was doing felt like, braking in a car like that is a whole different thing!

I took a risk driving my car up to Winton and it was a pretty sombre moment when I realised i might be up for the cost of a flat bed to get the car back to town. Amazingly there was an offer from a fellow attendee to tow my car back on his trailer (his car was still road legal) and if it came to it that would have been much appreciated however

I managed to thread the broken portion of the camber arm back into the adjuster although this shortened the camber arm by about 15mm but at least the wheel wasn't rubbing on the spring anymore.

I fitted a couple of washer under the chassis side of the camber arm to space it out a bit but still ended up with like -6 deg camber on that wheel

Amazingly it held on like that and I was able to drive it the 3 hours back home.Honed - WEB: https://honeddevelopments.com/ FB: https://www.facebook.com/honeddevelopments

Comment

-

During the week I took the front rim to a tyre shop and got them to spin it up, they found the rim was pretty buckled

I'll look into getting it repaired but I'm now booked in for another event in August and I don't want to be worried about these wheels (i've had to get the other one repaired already) so i've ordered two RPF1's for the front .

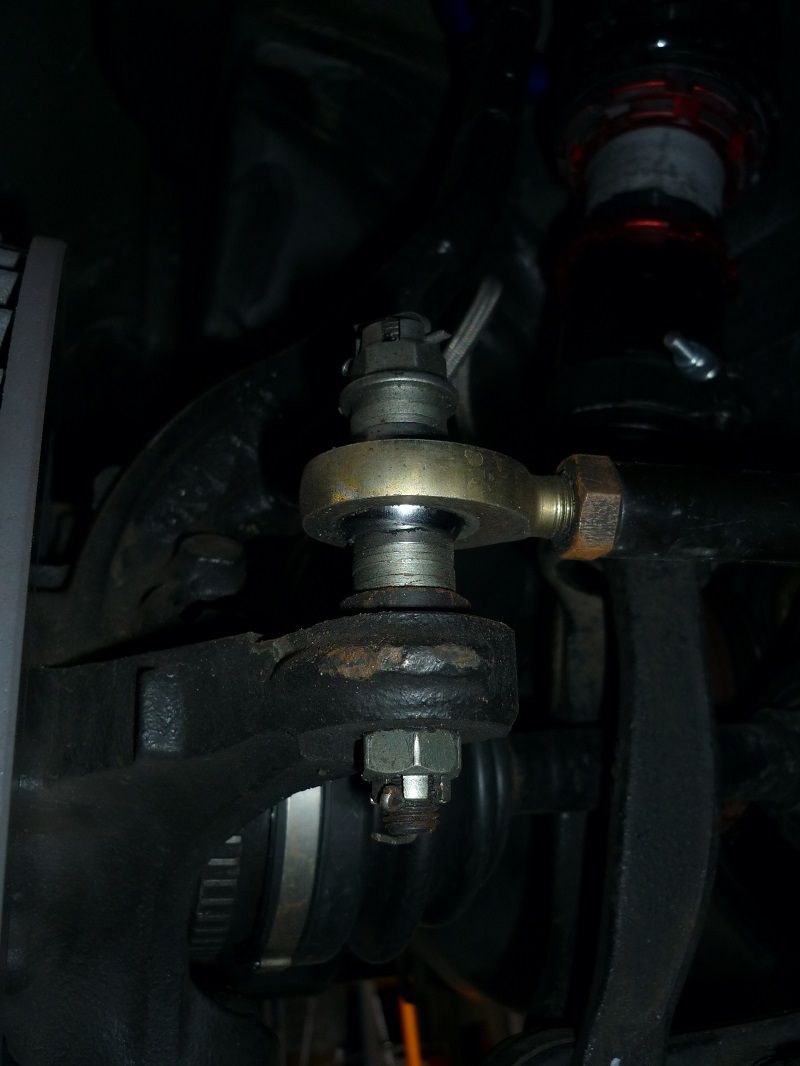

Today I got the replacement camber arms installed, went with hardrace

You can visualize how the asymmetrical design of the ebay camber arm loads the thread in bending.

I like that the hardrace camber arm is steel and that they even supply bevel washer between the locking nuts and the adjuster body to prevent the nuts vibrating loose, the only thing i don't like about the hardrace part is that the threaded portion is welded the the bush sleeve but you couldn't forge or machine that part from one piece and still sell them for under $200

Camber arm installed

If anyone was wondering what urethane LCA bushes look like after 12 months, check out the image below

The bush has fallen apart all around the crush tube, i replaced the urethane bushes I had in the lca with some hardrace hardened rubber bushes.

The shock fork was much easier to install over the standard style rubber bushes than the urethane.

Nice shot of the front MCA red coilovers in the wheel arch, you can just see the little brake line bracket i made up

I was glad to see that even with a decent hit to the wheel my tie rod stub is undamaged! I've done probably 3000 kms with the rod end style tie rod kit installed and no there is no play in the rod end and i haven't had any other issues with them.

In those 4-5 laps I got to complete at Winton I got the impression that the brake situation has been improved with the 260mm rear rotors and slightly larger rear pistion caliper. I brought Fred Puhn's Brake Handbook which is an excellent guide to braking systems and has helped me work out what my next step should be.

I've ordered a set of Hawk blue pads for the rear so I don't have a pad bias contributing to the issue then I've decided to delete the booster and convert the car to unboosted brakes with a smaller master cylinder and modified pedal ratio.

I'll be getting rid of the standard proportioning valve and the splitting the brake circuits front to rear instead of diagonally, I'll then fit a tilton adjustable proportioning valve to the rear circuit and use that to fine tune the rear brakes

Hopefully in a few weeks time i'll know if all that lot fixes my issue! (just learning how to brake properly would probably be easier!)Honed - WEB: https://honeddevelopments.com/ FB: https://www.facebook.com/honeddevelopments

Comment

-

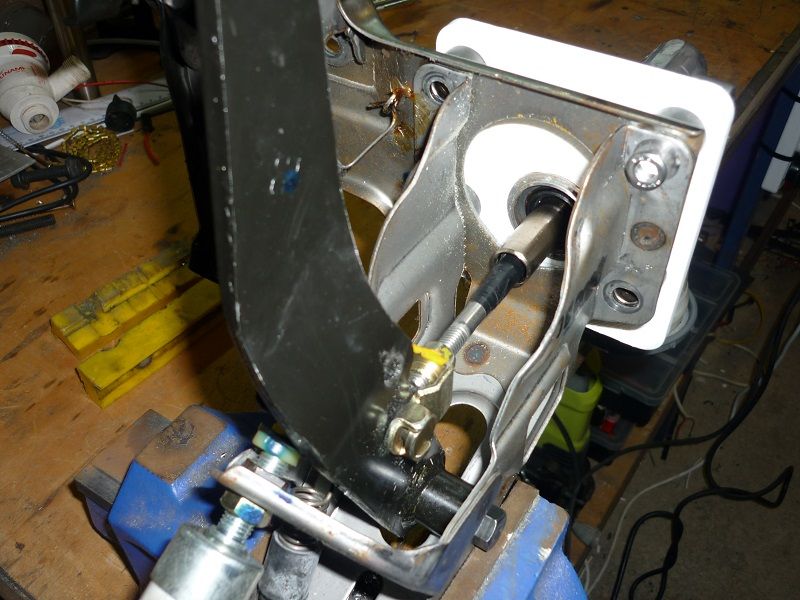

So on Sunday morning I went parts scavanging and collected a 7/8 MC and pedal box from a DC4

I took the booster from the dc4 as well and then cut the guts out of it to get the push rod shaft, this came in handy when trying to work out what length my new push rod will need to be

On Monday night I measured up the parts and had think about what would be required to mate the MC to the pedal box directly

I modeled up something resembling a bracket adaptor then managed to sneak it on the 3d printer overnight tuesday

This enabled me to check that I had measured the two bolt patterns correctly and then work out the what the length of the push rod needs to be

To achieve a 6:1 pedal ratio, I found that I needed to drill a hole 25mm up from the original in the pedal. Fortunately there is enough meat in the pedal to do this

I fashioned a push rod out of half of the original pushrod from the booster and half an m8 cap screw

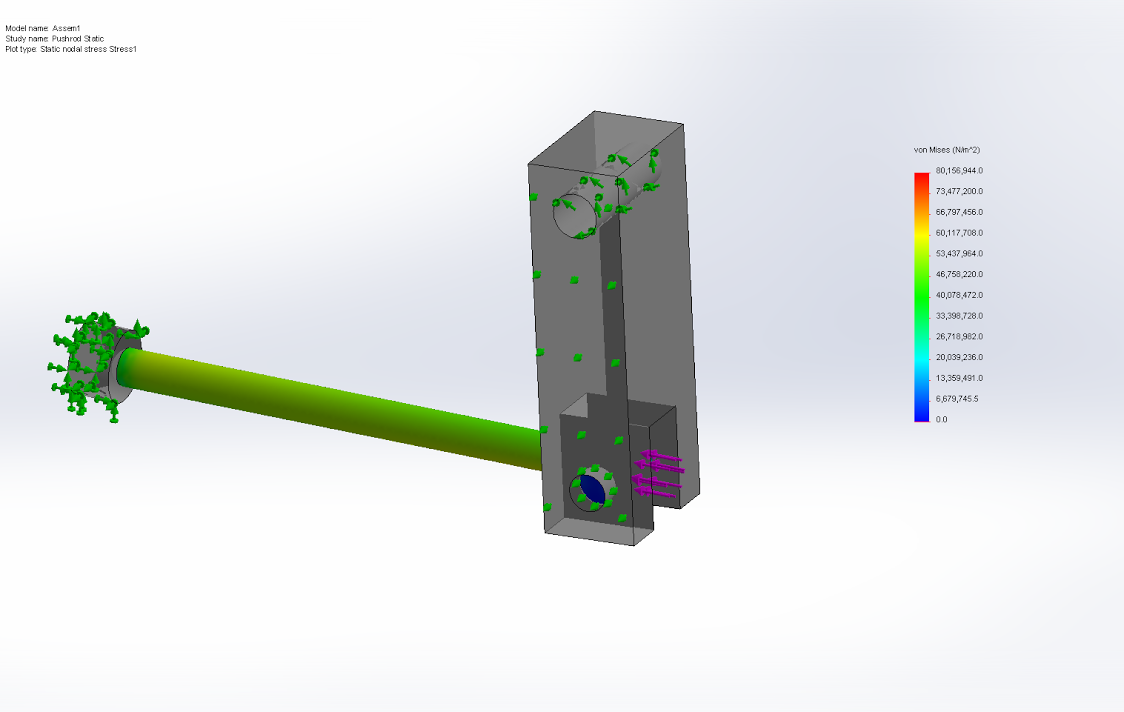

I quickly checked the stiffness of the pushrod with a rough simulation, turns out an 8mm push rod is plenty strong enough

Here you can see how the assembly will sit in the car

The printed bracket is strong enough that I can cycle the pedal through it's arc and check the clearance around the clevis and feel the free play,

My initial impression is that this set up will work out just fine!Honed - WEB: https://honeddevelopments.com/ FB: https://www.facebook.com/honeddevelopments

Comment

-

So the RPF1's I ordered turned up last week and on Friday i dropped them off at the tyre shop to swap my tyres over.

Specs on these wheels are 17" x 9.5" +35

I'm going to keep pushing with this 17/16 stagger idea, even through it's causing me issues at every turn haha

I've spent the last week getting the 7/8 master cylinder mounted into the car

The firewall needed a little die grinding to allow clearance for the master cylinder in it's new position

I didn't take any photo's of the new pushrod before I installed it, but what i did was have the machine shop who milled the adapter plate, take an m8 bolt cut it to the length i worked out that I would need it to be then on the cut end recreate the profile from the oem booster pushrod.

This worked out great; the result is a pushrod with rolled threads (stronger than cut threads), no welds (so no HAZ), zinc plated, the required hardness (or close to it) and the correct profile to match the master cylinder

You can see the adaptor plate in this picture:

I had to make a couple of 2.5mm spacer plates to space the adaptor plate out from the firewall so that it cleared the firewall joggle

I then found that my master cylinder reservoir was hard up against the edge of the firewall that the rear of the bonnet seals against, so I made another couple of spacers to bring the MC another 5mm out

You can see how close it is in the photo above.

With everything bolted up i can still get the reservoir cap on and off so I run it like this for now and if I feel like getting another adapter machined up i'll adjust the design to compensate.

You can see where the Tilton proportioning valve has ended up, I was a bit confused as to how to actually adapt the hardlines into the tilton unit. The instructions pdf that Tilton provides is not very clear on what you're supposed to do (or i'm not very perceptive haha)

What I've done is use a bubble flare on the tube and a tube nut with a section of non-threaded shank at the end, initial impression is that this has sealed but I won't know for sure until we get the system bleed up properly.

Speaking of bleeding! It turns out that the "tee" fittings i've sourced to converge the LHS and RHS hardlines, of the front and rear circuits respectively are not the type suited to the "inverted flare" that our Honda hardlines use.

When we tried to bleed the system this morning the fluid just pushed out the top of the fitting!

Luckily it looks like Brakequip make a "tee" that has the correct inverted flare style female connections and so I'll order a couple of those on Monday and we should be back in business!

This little project has given me quite the education in brake system components!Honed - WEB: https://honeddevelopments.com/ FB: https://www.facebook.com/honeddevelopments

Comment

-

So last weekend I got a couple of the correct inverted flare "T" fittings and bolted those into place, completing the manual brake conversion

As you can see I've just bent the original brake lines around to fit, less than ideal but I don't want to take the engine out just yet.

The first attempt to bleed the system resulted in a pedal with about 20mm of dead travel before it would feel firm.

I was eager to see where the brake bias had ended up so we took the car for a brief test drive anyway

My first impression was that the fronts were much less prone to "pinching" or locking up when you got on the pedal at high (for the road) speeds (100 - 80 km/hr)

I was happy for this to be the case as eliminating that issue was the whole point of this exercise!

However if I held constant pressure on the pedal, as the car slowed though the 40 km/hr range it would still lock the fronts.

Now it could be argued that one should be easing off the pedal as the car slows down and on track that is the case but in this instance I was trying to identify which wheels would lock first.

So the modifications I've done haven't over powered the rear brakes, if anything it's still got front bias

For reference:

- This was with the proportioning valve adjusted to give the rear brakes full pressure.

- This was also with the 15 x 6 wheels and 195 tyres on up front.

I figured that it might be a different story with the larger wheels and stickier tyres, it's logical that the brake balance would shift rearward with that combo on the front.

As I was driving it around the block I noticed the temp gauge start to move around, that set the warning bells ringing as normally the temp gauge is rock solid

I found it odd through because the needle would settle back to its normal position when I was idling at lights (where i would have expected the temp to soar if there was an issue)

Last time I drove it, the car was fine and the chance of the water pump failing just sitting in the driveway is pretty slim.

My guess was that the temperature sensor was playing up somehow

I parked the car for a week and then this morning when I had a chance to get back to it

I started by cleaning the temperature sensor, when I first pulled it off I could see that there was some oil around it and it way pretty dirty in general

After cleaning the plug out I applied some dielectric grease to the terminals and reinstalled it

then I connected the laptop to the ECU and checked all the parameters to do with the cooling system.

- The electric fan was working, I could switch it manually and check that.

- The electric fan is set to come on at 94 degrees

- The analog input value from the temp sensor seemed to match the movement of the gauge on the dash

- I let the car run for about 20 mins in the driveway and it came up to temp and then regulated temperature just fine.

Who knows, maybe it was just the sensor playing up on that day.

Back to the manual brake conversion story

I bled the brakes again, this time quite a lot of air came out of the rear circuit and the pedal feel improved to something resembling normal pedal feel

It probably needs yet another bleed but you can feel that it's building pressure right from the top of the pedal now.

I bolted the track day wheels on and took the car for another drive

The temperature gauge came up to it's usual position and stayed there so that was good.

The brakes felt much better this time,

The feel is bit wooden, the brakes don't have that instant bite at 20 km/hr you get with a boosted set up.

Pedal effort is different, you do have to press down a little harder initially (and increase following distances!) but you adjust to it quickly and it doesn't feel so hard that your leg would tire out or anything like that.

It still locked the fronts with the track wheels up front but only at lower speeds so i don't know if that's really an issue or not.

I don't think I'm going to be able to get a real gauge of where the brakes are at until I run the car on track again, you just can't replicate track conditions on the road

The headlight lenses have been looking rather dull and yellowed so I decided to try rejuvenate them with a head light restoration kit

Before

After

At the last event I found it quite difficult to get in and out of the Sparco seat, with my short legs, the front of the seat is quite close to the bottom of the steering wheel. This makes it hard to get your waist out of the seat

I've installed a flip up boss to resolve this issue

And finally

I've brought a daily/tow vehicle

Last edited by Grant@Honed; 19-07-15, 12:23 AM.Honed - WEB: https://honeddevelopments.com/ FB: https://www.facebook.com/honeddevelopments

Last edited by Grant@Honed; 19-07-15, 12:23 AM.Honed - WEB: https://honeddevelopments.com/ FB: https://www.facebook.com/honeddevelopments

Comment

Comment