Hey mate, good meeting you the other day (thanks for the diff!). Hopefully I can get around to installing it soon.

Just re-read through your thread, some good things going on. We have fairly similar setups, so I am finding this thread very useful!

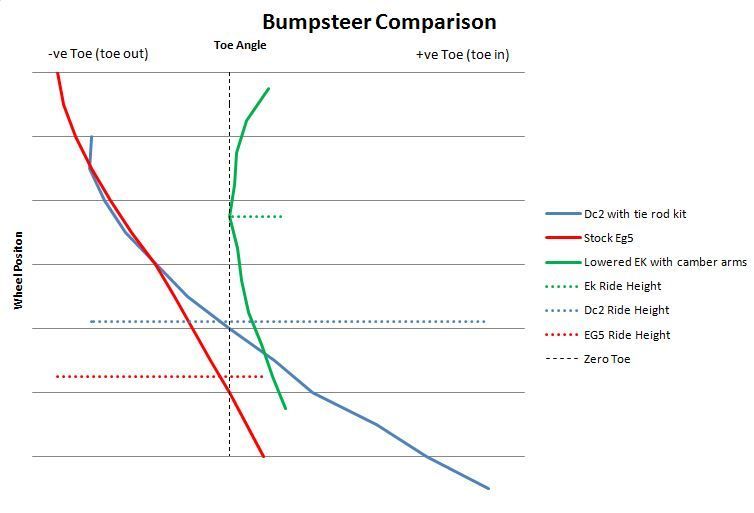

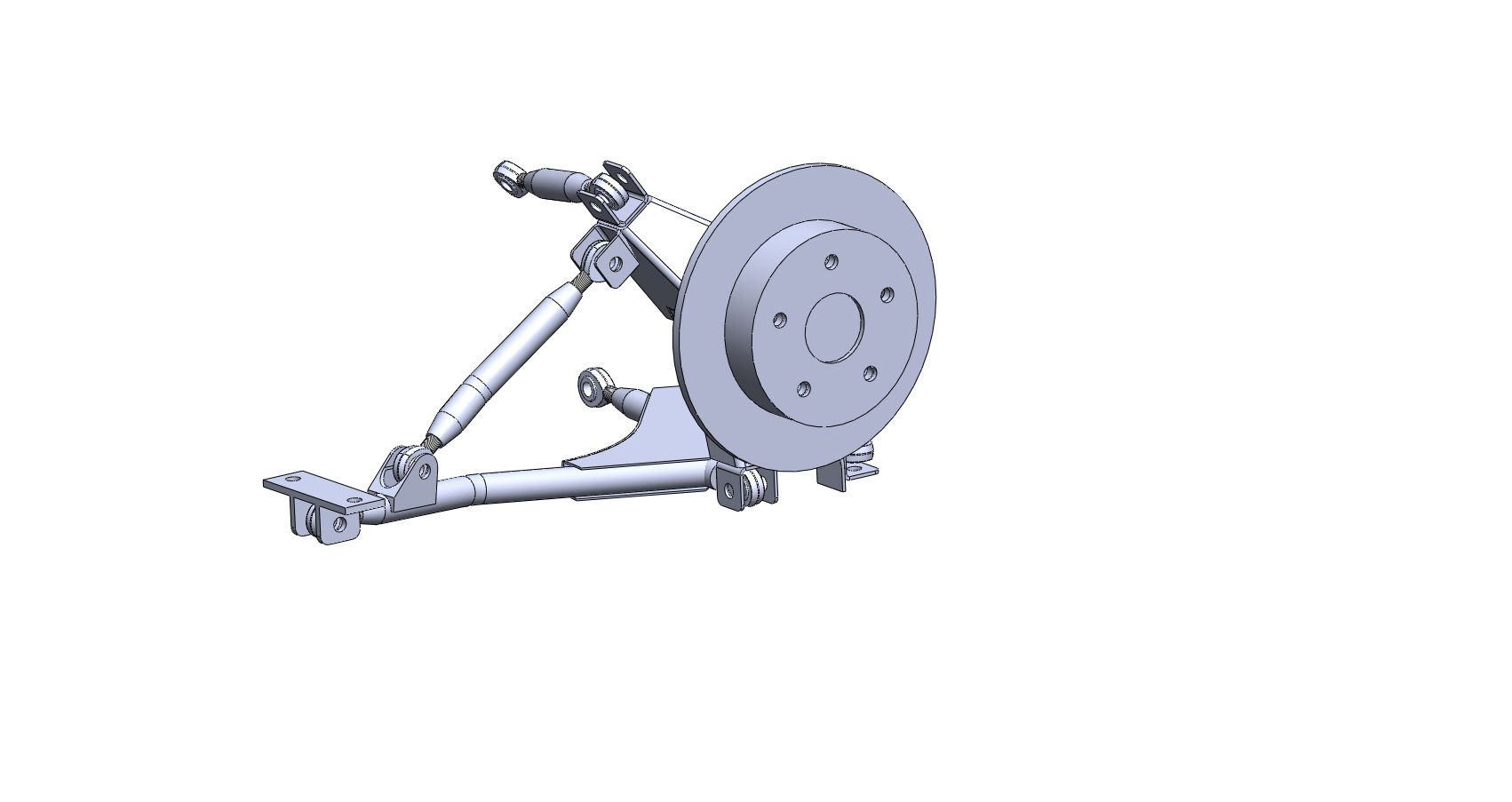

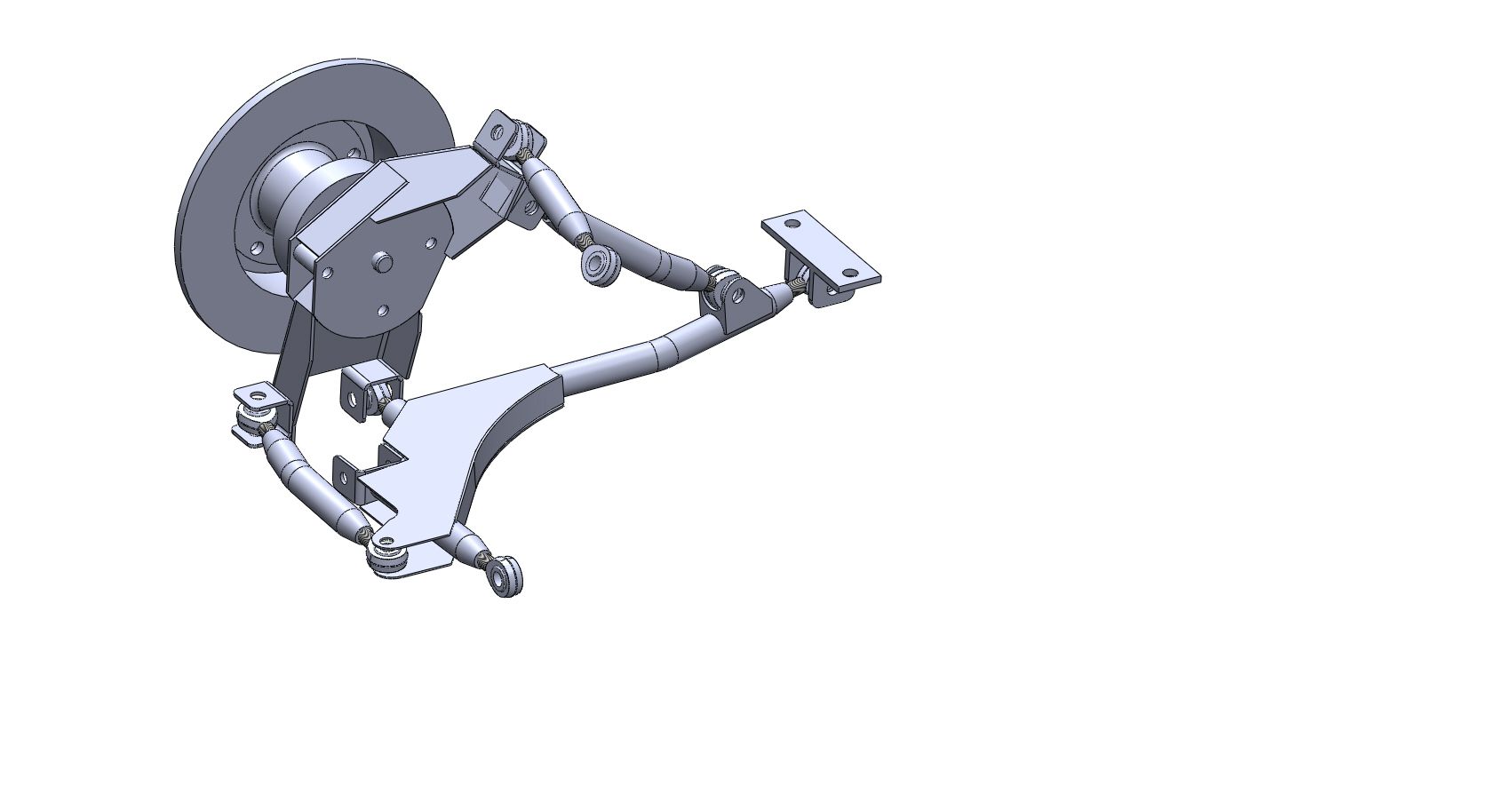

Maybe I missed it, but have you got any feedback on your final roll centre and toe link adjustments on the track or even just general driving?

Also, what did you base the swap from 15" to 17" rims on? Do you feel that the swap gave you any specific benefits?

Just re-read through your thread, some good things going on. We have fairly similar setups, so I am finding this thread very useful!

Maybe I missed it, but have you got any feedback on your final roll centre and toe link adjustments on the track or even just general driving?

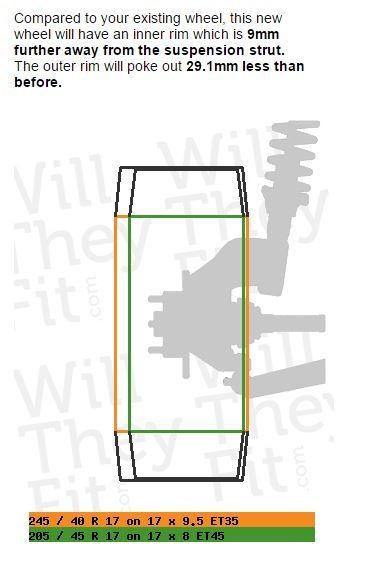

Also, what did you base the swap from 15" to 17" rims on? Do you feel that the swap gave you any specific benefits?

Comment