Hi Guys,

Joined clubitr while ago and decided it was time to put together a timeline of my DC2 Track car. This is my first dedicated track car, although it is still road registered so it won't be getting anything too crazy.

I'll hopefully update this thread over the next few weeks to get it up to current....

Car Details

Bought the car April 2013, it wasn’t in the best shape. A very early example of the DC2, October 1993 build.

The good and not so good points:

- Pretty much stock Vti-r

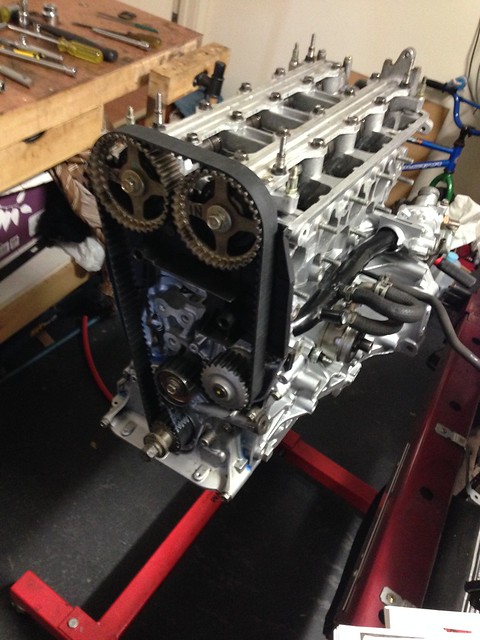

- B18C drove ok, but was using about 1 litre of oil a month

- Engine mounts shot, everytime the throttle was let off resulted in a huge thump. It felt like running over a brick in the road.

- Body work was average, a few spots the clear coat was peeling. Both front and rear bumpers had minor creases and dings

- Only visible mod was a beaks bar on the rear and felt like a short shifter installed too.

- Came with the stock spoiler and a mugen type front lip not fitted to the car.

- Interior was in pretty good condition, although this didn’t bother me too much given my plans for the car

- It was cheap, the current owner was leaving for O/S and selling with 8 months rego although I had to organise the RWC myself to transfer into my name.

I can't find any photos of it when I first got it, but here it is a short time later. The pics are after suspension change, new wheels, new red badges front/rear (original ones were stolen by some jerk plus red goes faster) and I refitted the stock spoiler.

IMG_0420

IMG_0420

IMG_0414

IMG_0414

You can see some of the excellent "repair" work done on the bumper here. The touch up paint used is a different colour as well as being raised about 10mm from the surface. I think it would look better unreapaired.

IMG_0137

IMG_0137

The current owner was pretty shocked when I said I was going to use it as a track car, he couldn’t see the potential given the current state of engine guzzling oil and basically crashing around loose in the engine bay, but given some basic maintenance it was heading in the right direction.

Joined clubitr while ago and decided it was time to put together a timeline of my DC2 Track car. This is my first dedicated track car, although it is still road registered so it won't be getting anything too crazy.

I'll hopefully update this thread over the next few weeks to get it up to current....

Car Details

Bought the car April 2013, it wasn’t in the best shape. A very early example of the DC2, October 1993 build.

The good and not so good points:

- Pretty much stock Vti-r

- B18C drove ok, but was using about 1 litre of oil a month

- Engine mounts shot, everytime the throttle was let off resulted in a huge thump. It felt like running over a brick in the road.

- Body work was average, a few spots the clear coat was peeling. Both front and rear bumpers had minor creases and dings

- Only visible mod was a beaks bar on the rear and felt like a short shifter installed too.

- Came with the stock spoiler and a mugen type front lip not fitted to the car.

- Interior was in pretty good condition, although this didn’t bother me too much given my plans for the car

- It was cheap, the current owner was leaving for O/S and selling with 8 months rego although I had to organise the RWC myself to transfer into my name.

I can't find any photos of it when I first got it, but here it is a short time later. The pics are after suspension change, new wheels, new red badges front/rear (original ones were stolen by some jerk plus red goes faster) and I refitted the stock spoiler.

IMG_0420

IMG_0420 IMG_0414

IMG_0414You can see some of the excellent "repair" work done on the bumper here. The touch up paint used is a different colour as well as being raised about 10mm from the surface. I think it would look better unreapaired.

IMG_0137

IMG_0137 The current owner was pretty shocked when I said I was going to use it as a track car, he couldn’t see the potential given the current state of engine guzzling oil and basically crashing around loose in the engine bay, but given some basic maintenance it was heading in the right direction.

Comment