Hi All,

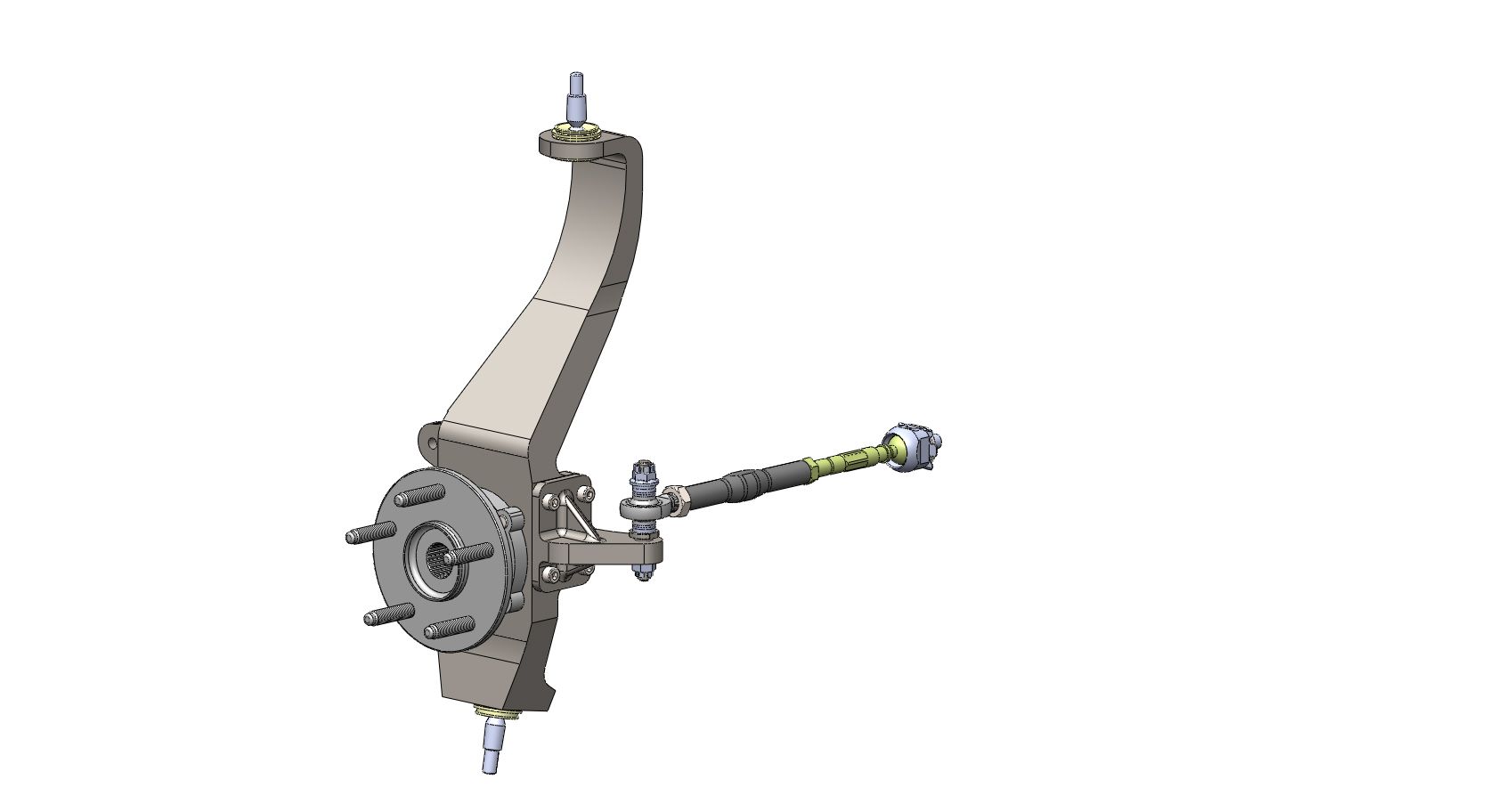

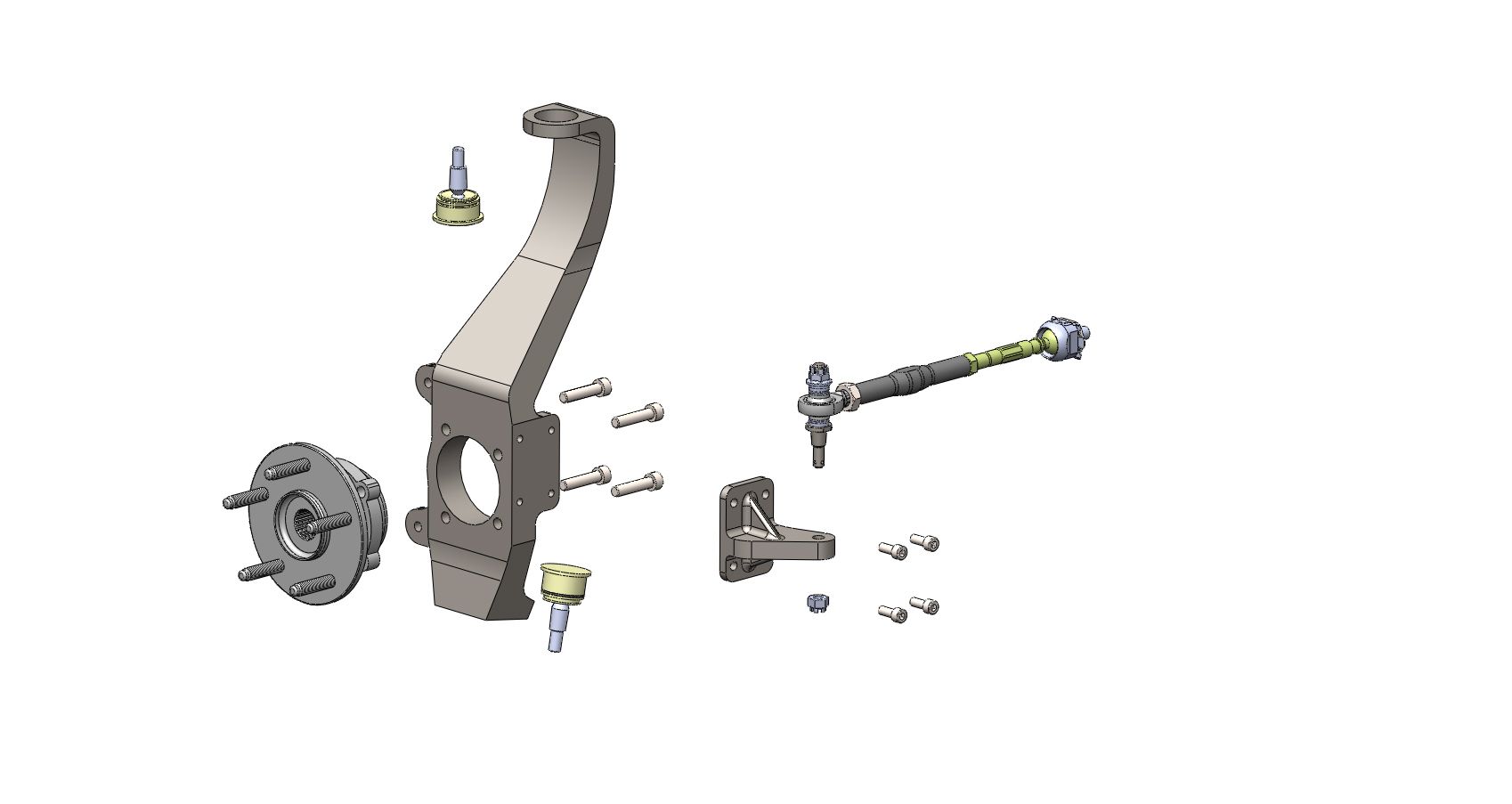

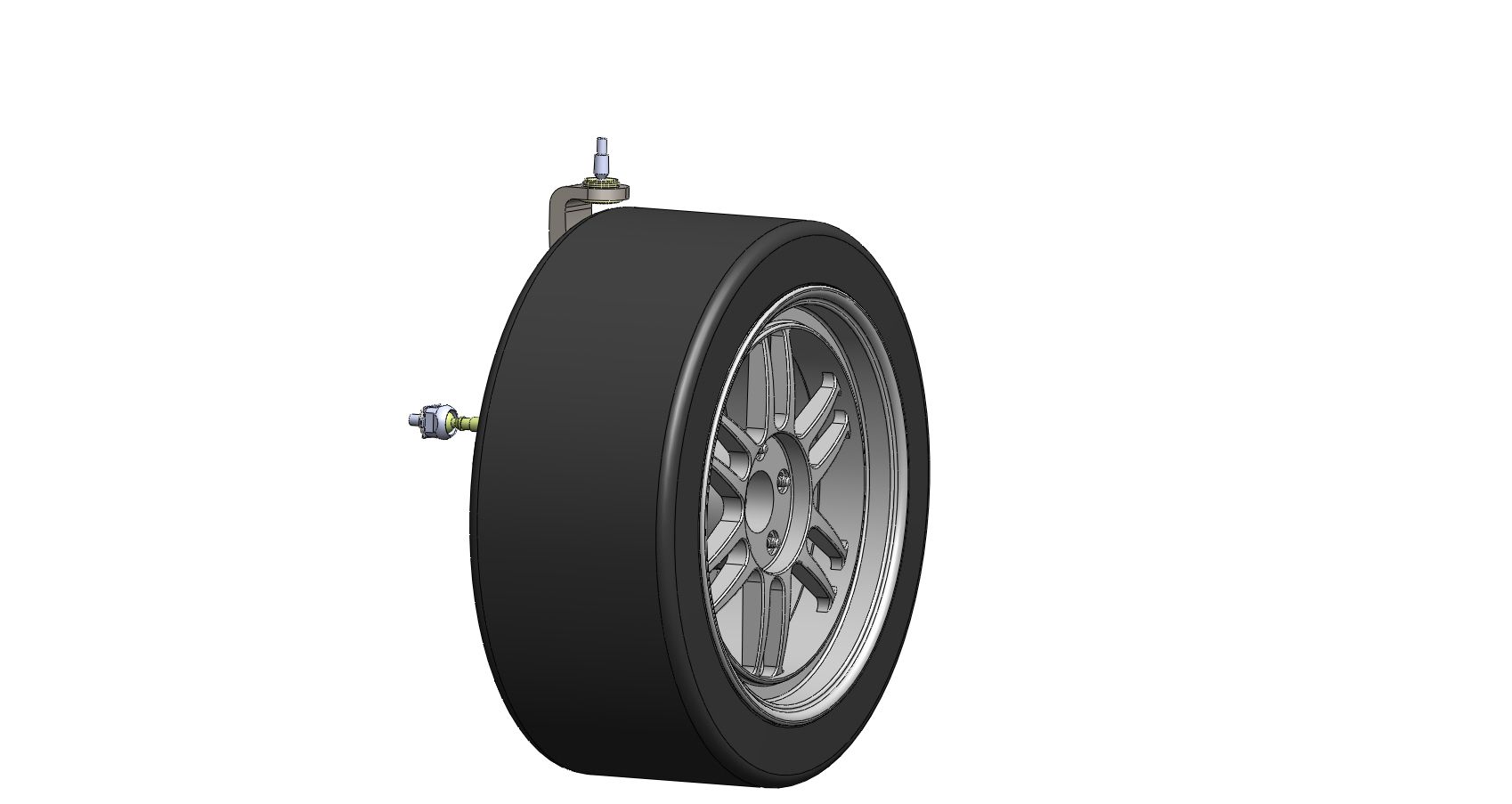

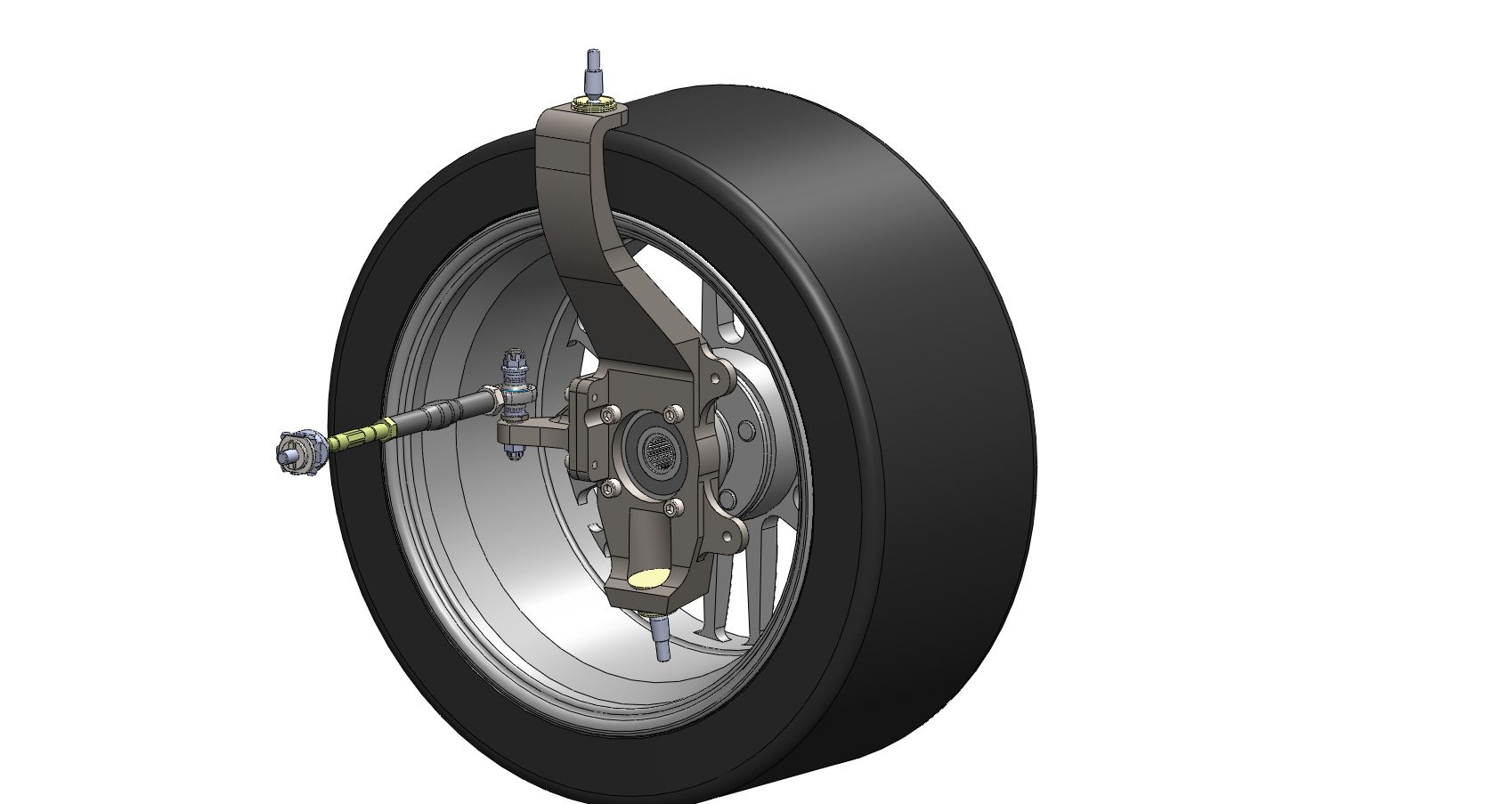

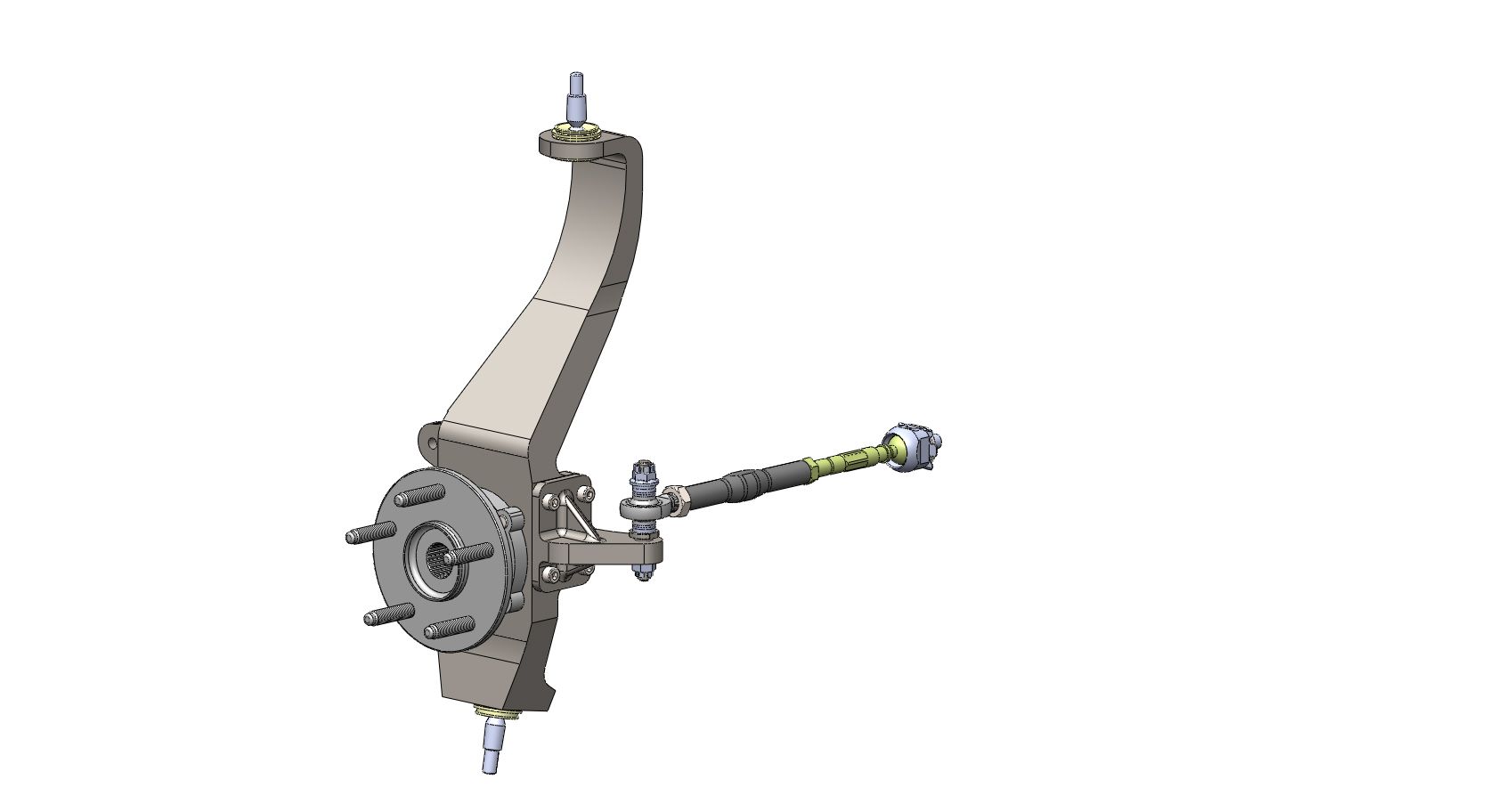

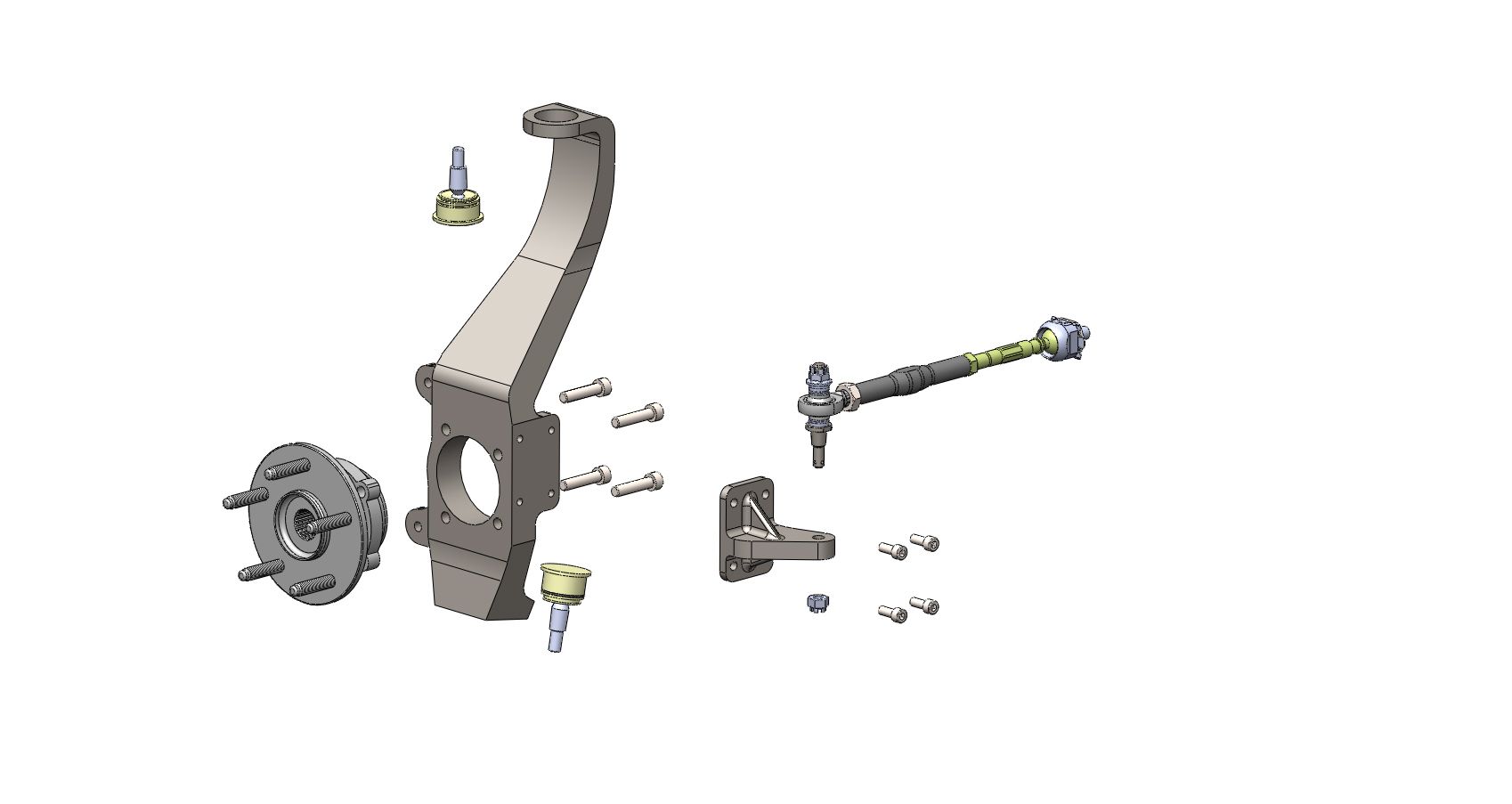

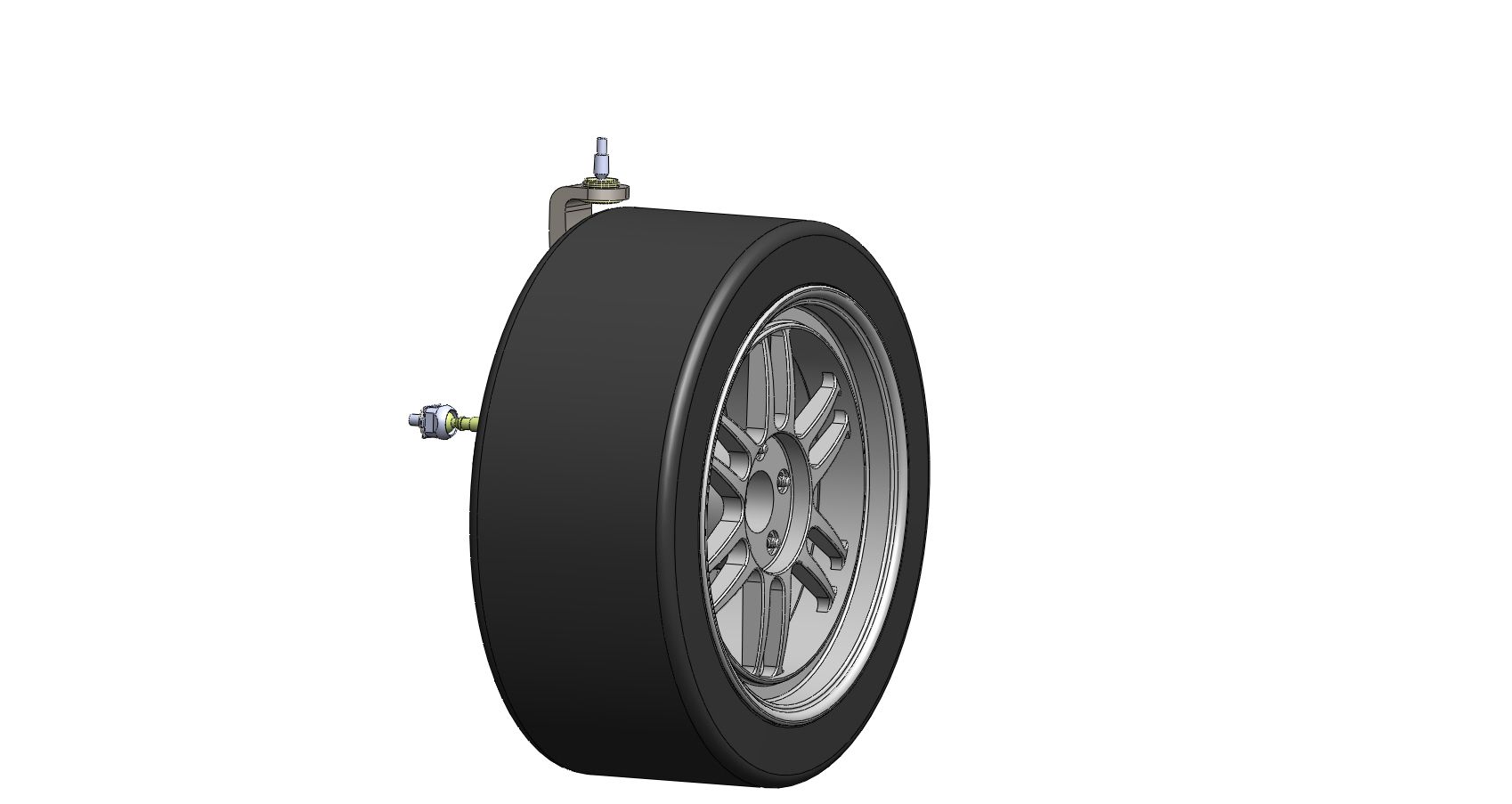

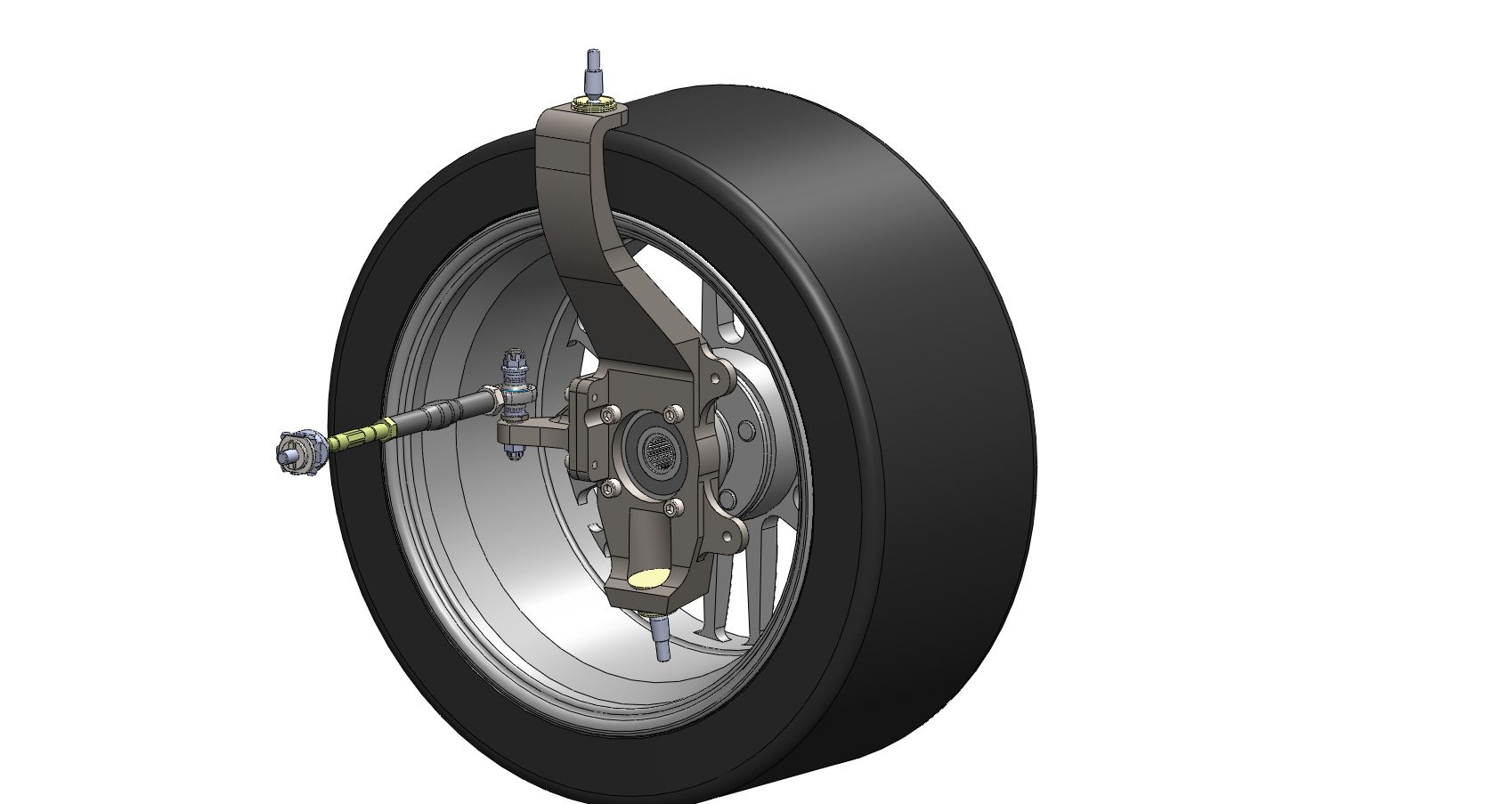

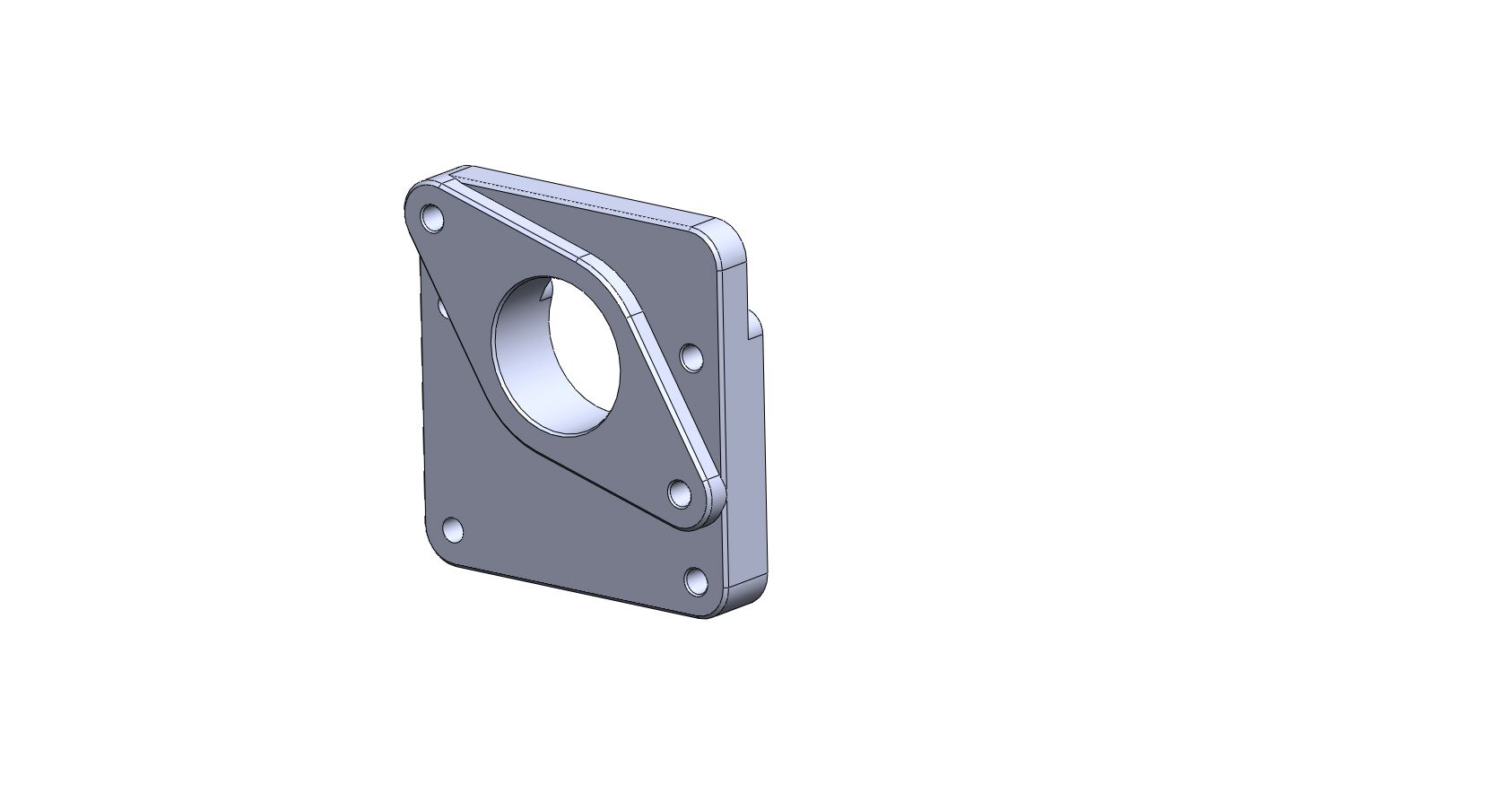

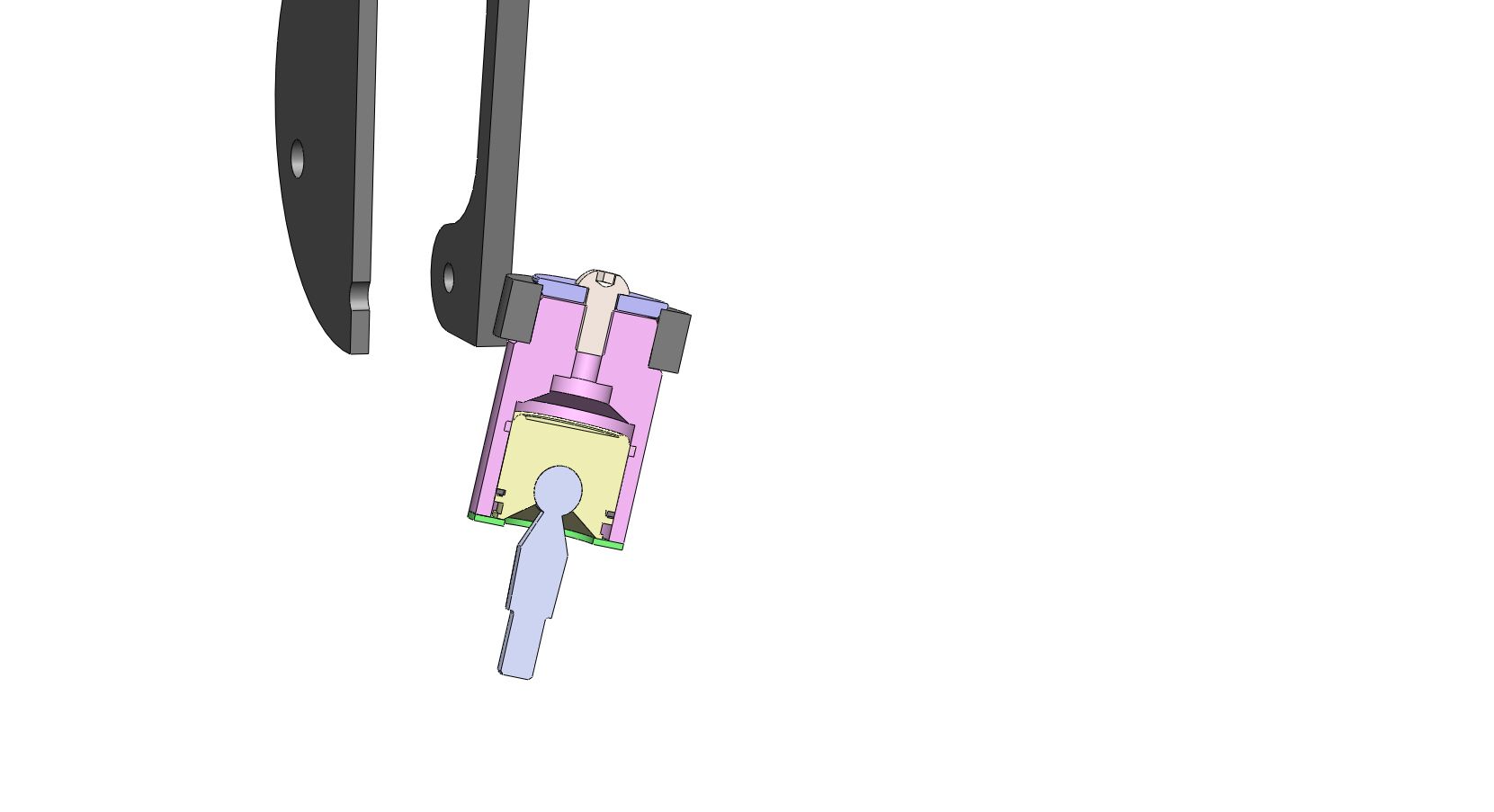

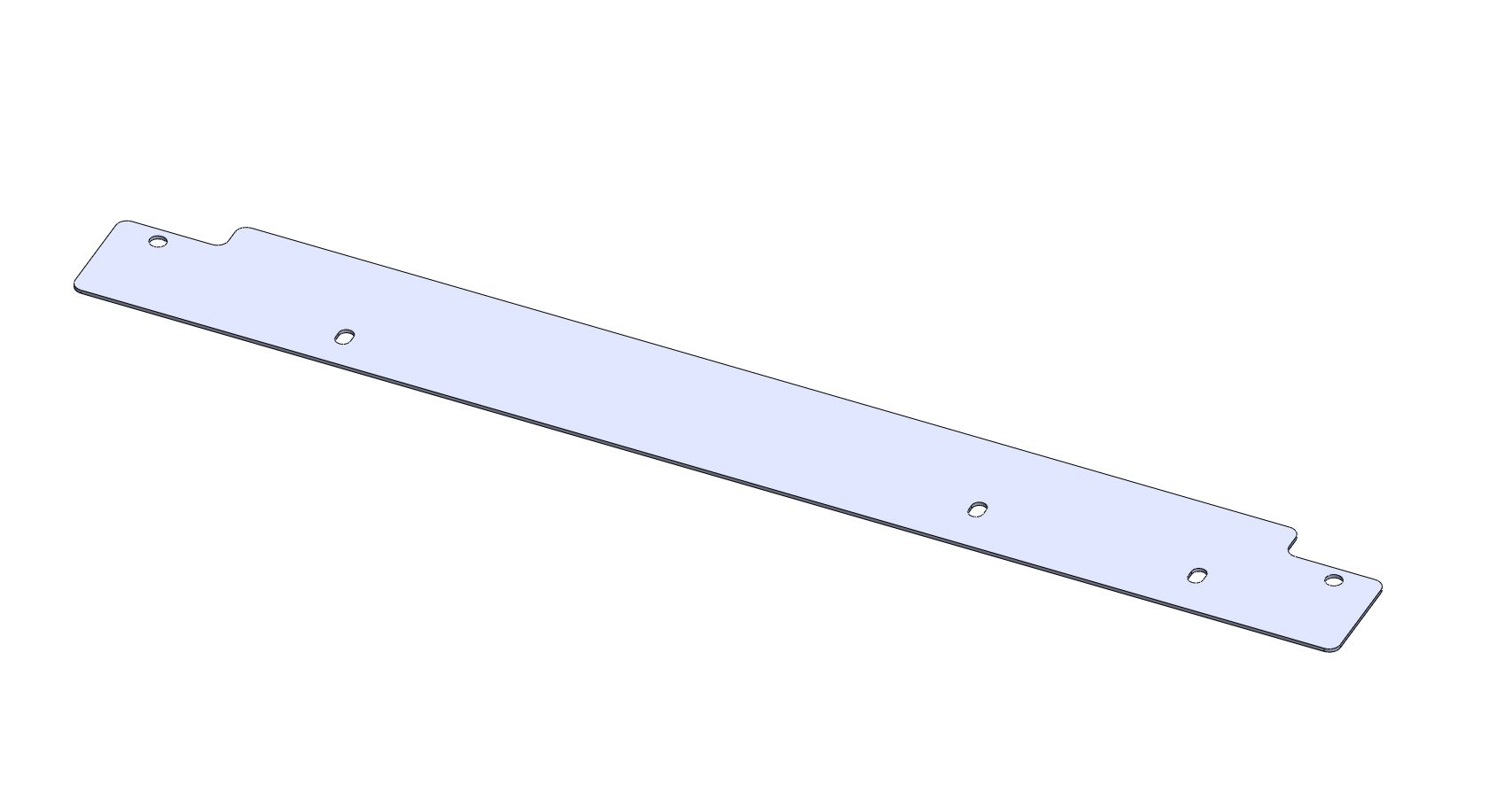

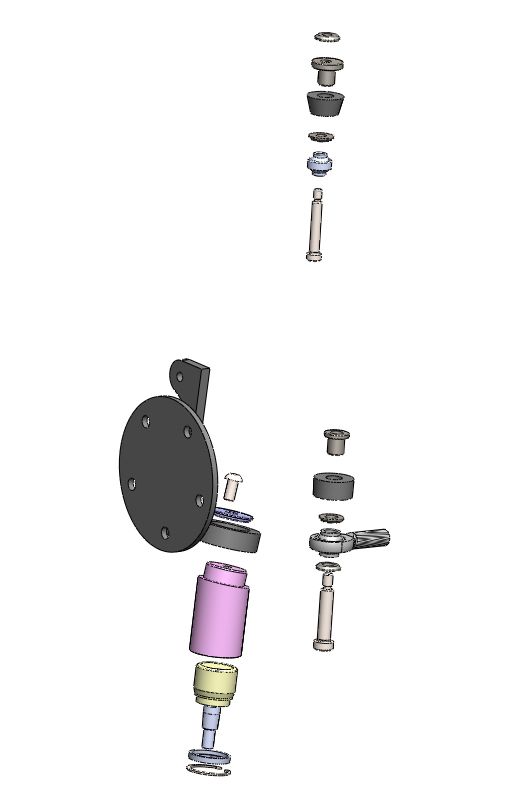

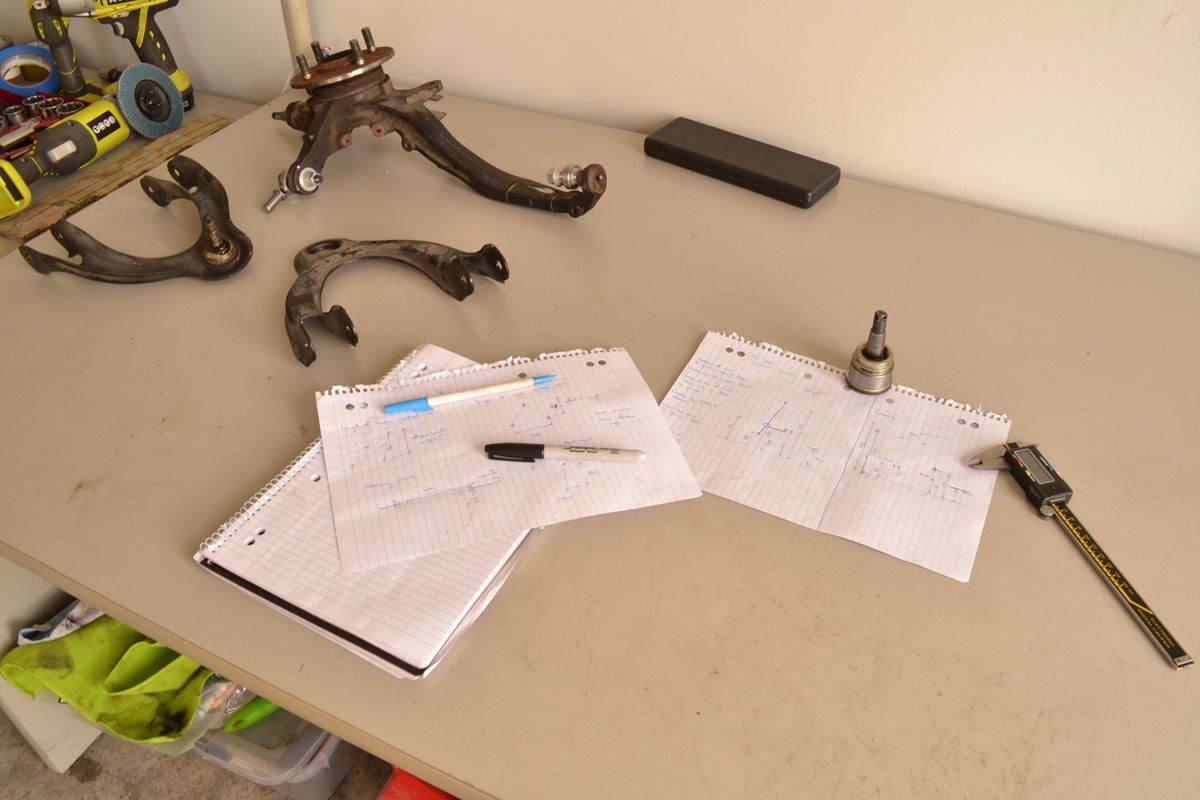

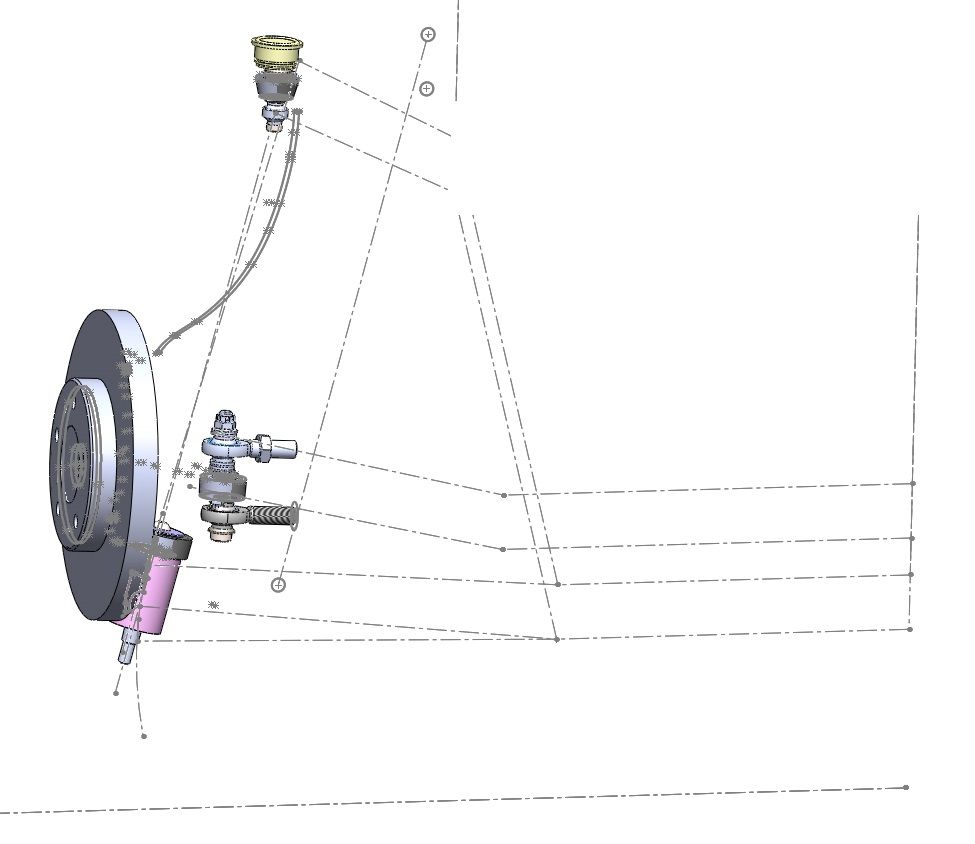

Here are some concept images of my front knuckle design

The keen eye'd among you will notice I have two ball joints in knuckle and that the upper ball joint is upside down compared to normal

This is an idea i'm perusing and if the geometry works out I might not have to cut and relocate the inboard end of the upper control arm (which would be nice)

Expect lots of changes between what is shown here and the final outcome but i wanted to keep the thread updated

I'm not even sure what method of manufacture to go with yet!

In other news, the engine has been cleaned up

Yesterday I received a delivery of OEM parts

- New sump gasket

- Head coolant passage block off plug

- New o-rings for coolant bypass tube

- Intake gasket

- Gearbox side crank seal

So i'll put those aside for when they are required.

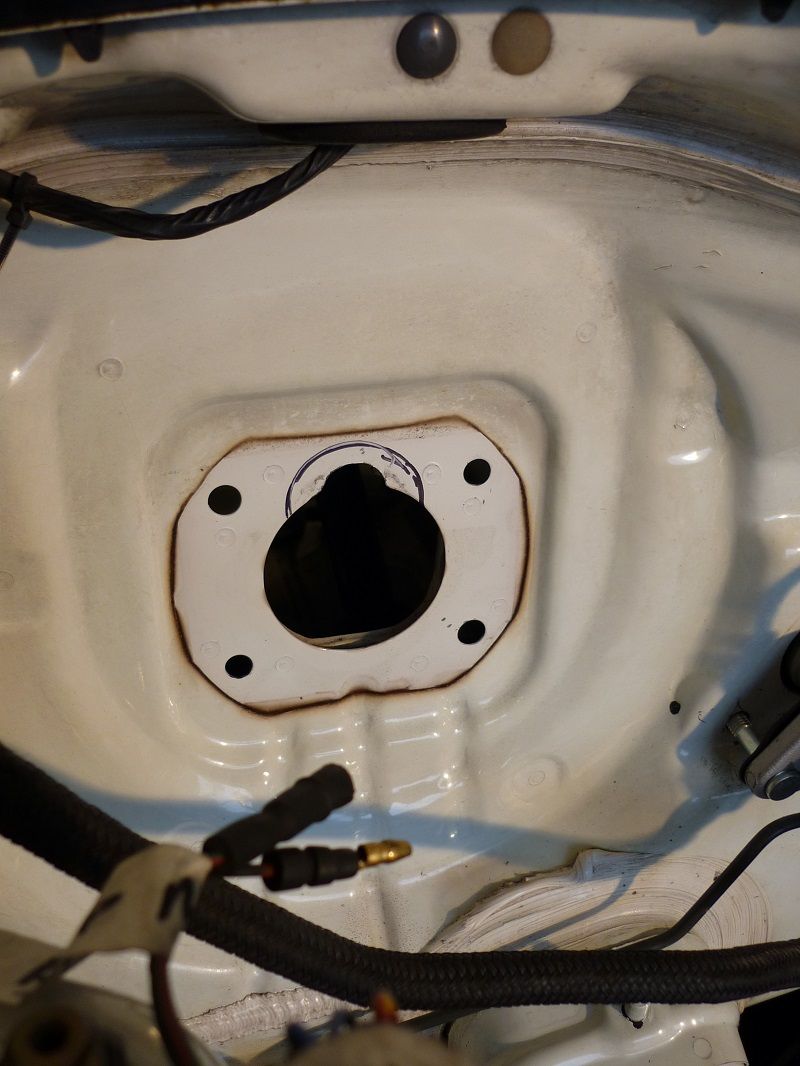

Next job on the shell is to drill out the spot welds and remove the brackets that mount the half size radiator and ac condenser

Then work out how i'm going to mount the Dc2 radiator in there

Here are some concept images of my front knuckle design

The keen eye'd among you will notice I have two ball joints in knuckle and that the upper ball joint is upside down compared to normal

This is an idea i'm perusing and if the geometry works out I might not have to cut and relocate the inboard end of the upper control arm (which would be nice)

Expect lots of changes between what is shown here and the final outcome but i wanted to keep the thread updated

I'm not even sure what method of manufacture to go with yet!

In other news, the engine has been cleaned up

Yesterday I received a delivery of OEM parts

- New sump gasket

- Head coolant passage block off plug

- New o-rings for coolant bypass tube

- Intake gasket

- Gearbox side crank seal

So i'll put those aside for when they are required.

Next job on the shell is to drill out the spot welds and remove the brackets that mount the half size radiator and ac condenser

Then work out how i'm going to mount the Dc2 radiator in there

Comment