**Here again moving my build thread on my Honda RT4WD Wagon from Honda-Tech to ClubITR like I did with my track hatch build thread! Enjoy!**

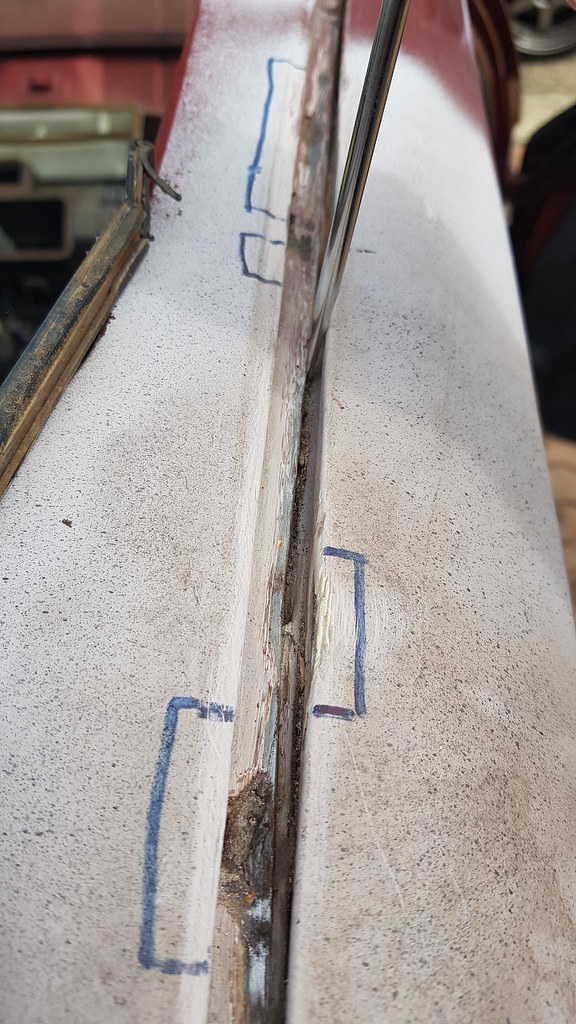

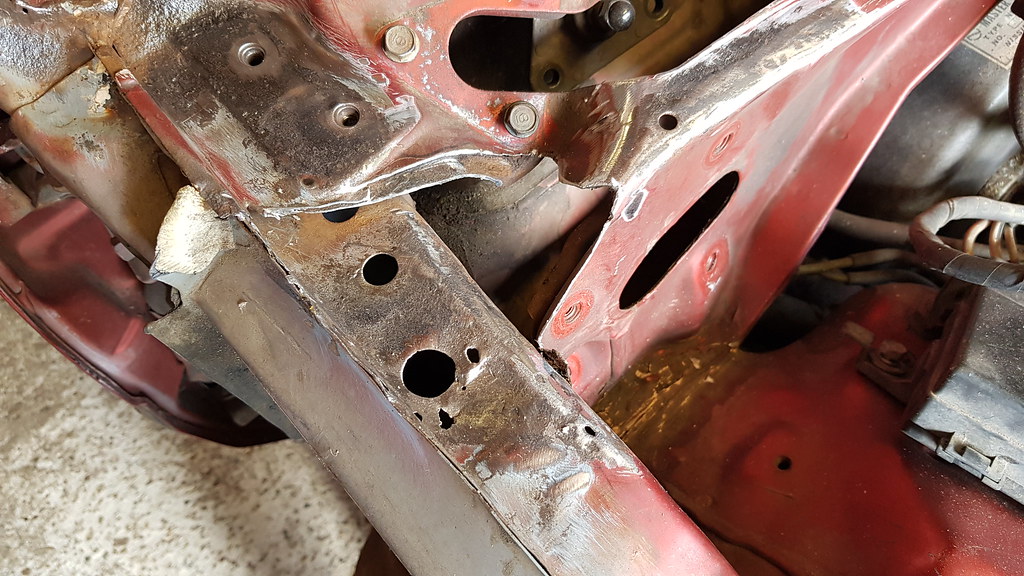

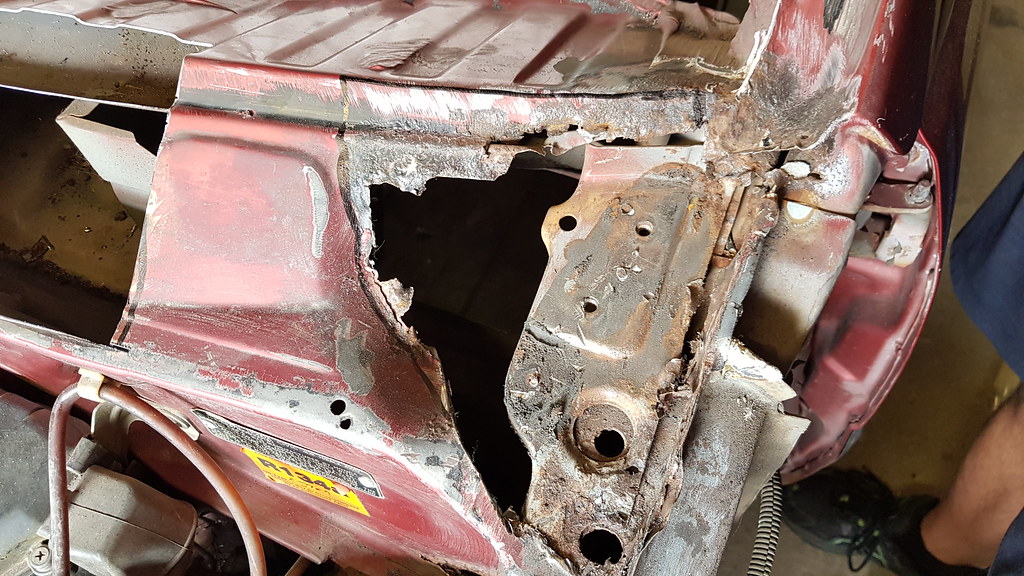

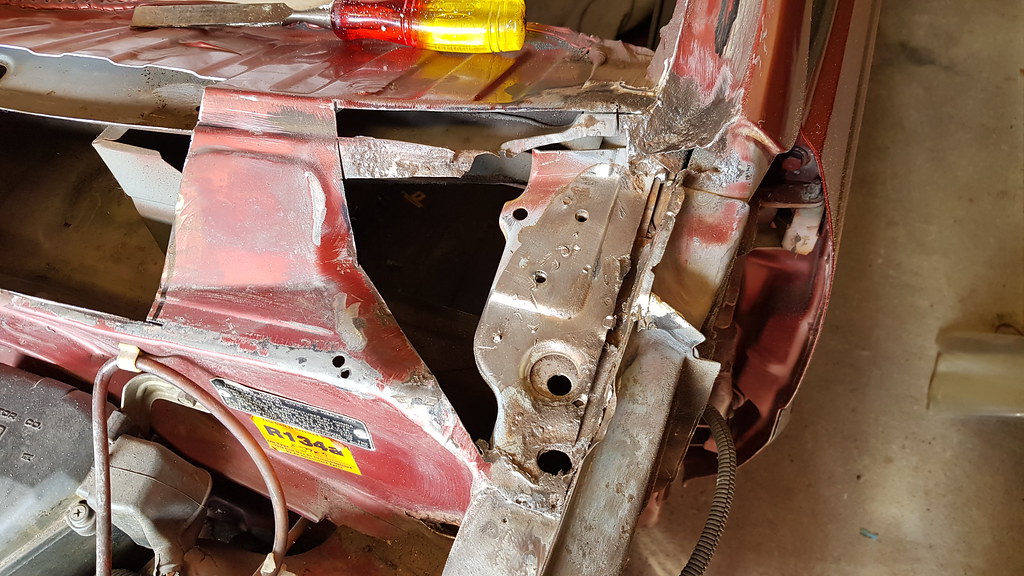

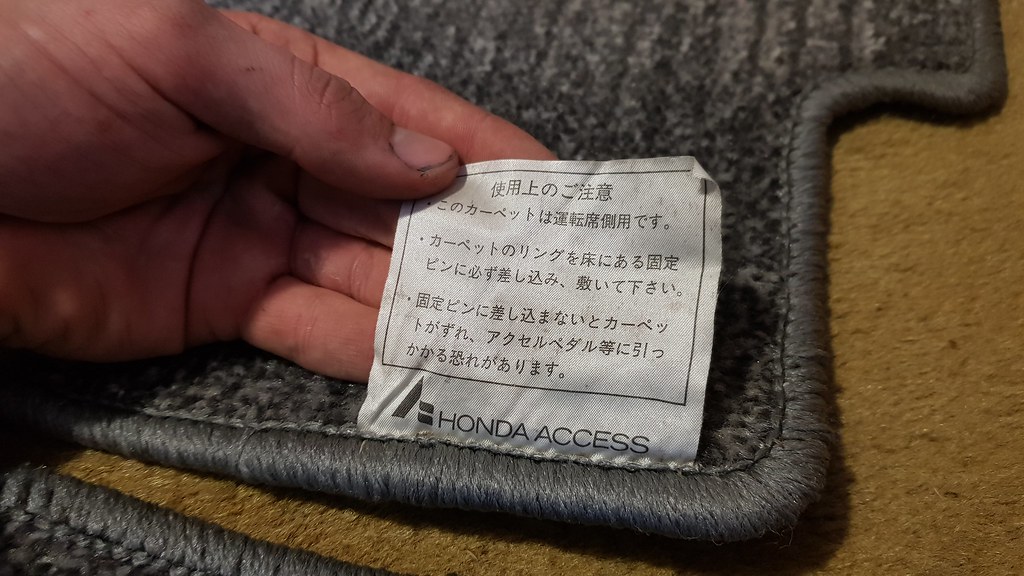

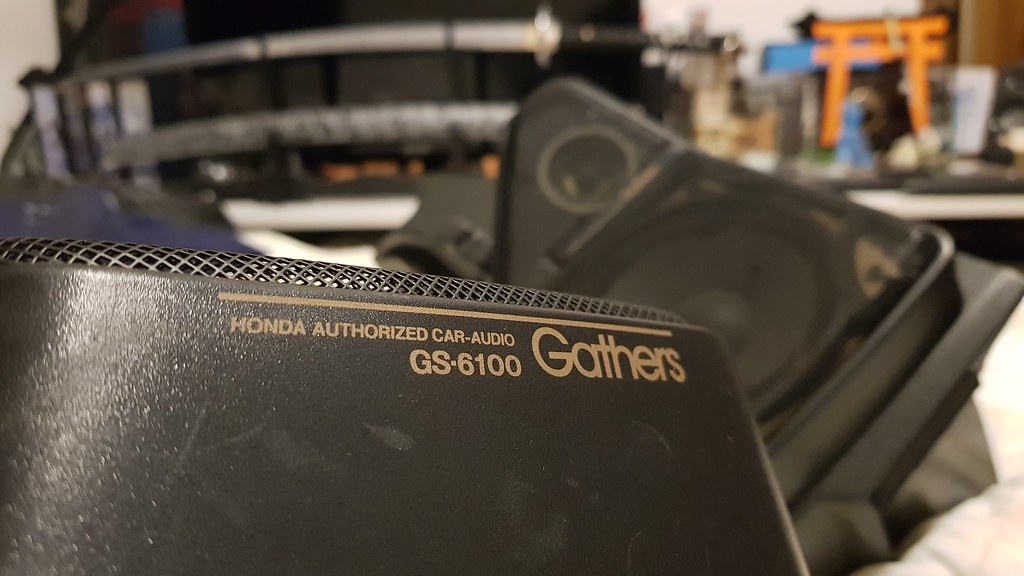

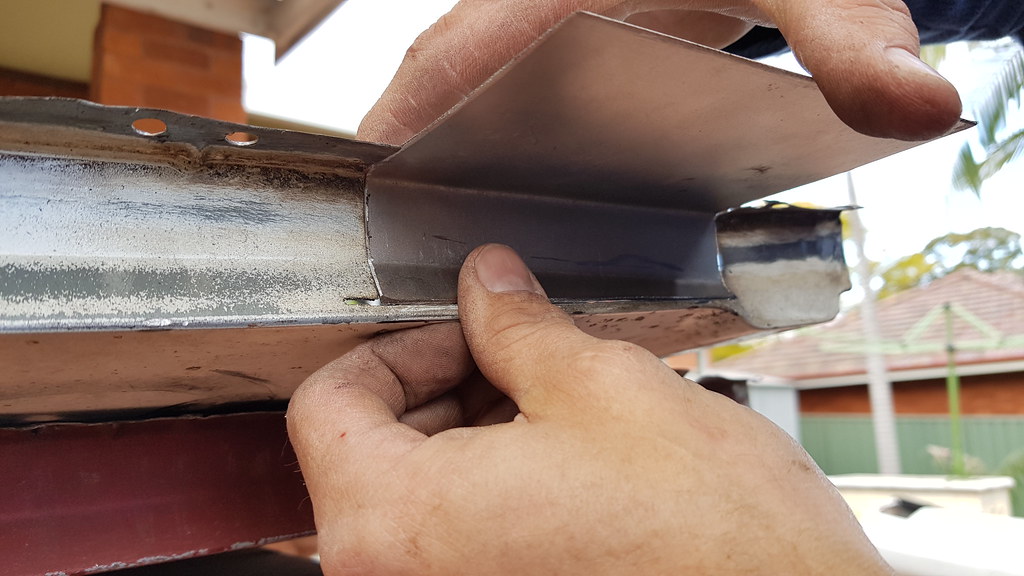

Yo! So I've been in the old school Honda game for over 4yrs now with my track/street built hatch (https://honda-tech.com/forums/honda-...chbox-3251019/) and I've now picked up a new project, a RT4WD Wagon! Plans with this some what barn find which has been off the road for 9 years is to restore it, make it look shmick, and slap a SOHC VTEC motor in it and turbo! I've always wanted to do a SOHC Turbo build, and which chassis would be better than a 4WD wagon hehe. Here's some starting photos for the old girl, bit rusty around the window but apart from that the rest of the chassis is somewhat clean!

Yo! So I've been in the old school Honda game for over 4yrs now with my track/street built hatch (https://honda-tech.com/forums/honda-...chbox-3251019/) and I've now picked up a new project, a RT4WD Wagon! Plans with this some what barn find which has been off the road for 9 years is to restore it, make it look shmick, and slap a SOHC VTEC motor in it and turbo! I've always wanted to do a SOHC Turbo build, and which chassis would be better than a 4WD wagon hehe. Here's some starting photos for the old girl, bit rusty around the window but apart from that the rest of the chassis is somewhat clean!

)

)

Comment