Cool man, I'm keen to check it out!

I'm going to try push through another round of suspension development in the next month so ill probably miss July and aim to enter an event sometime in August.

I'm going to try push through another round of suspension development in the next month so ill probably miss July and aim to enter an event sometime in August.

Keep it up.

Keep it up.

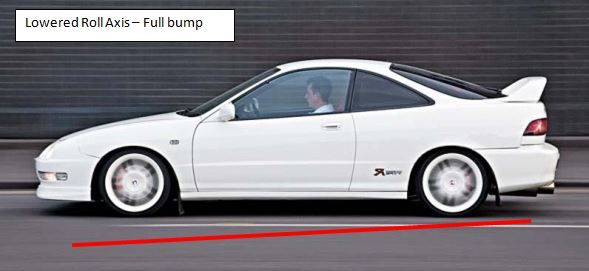

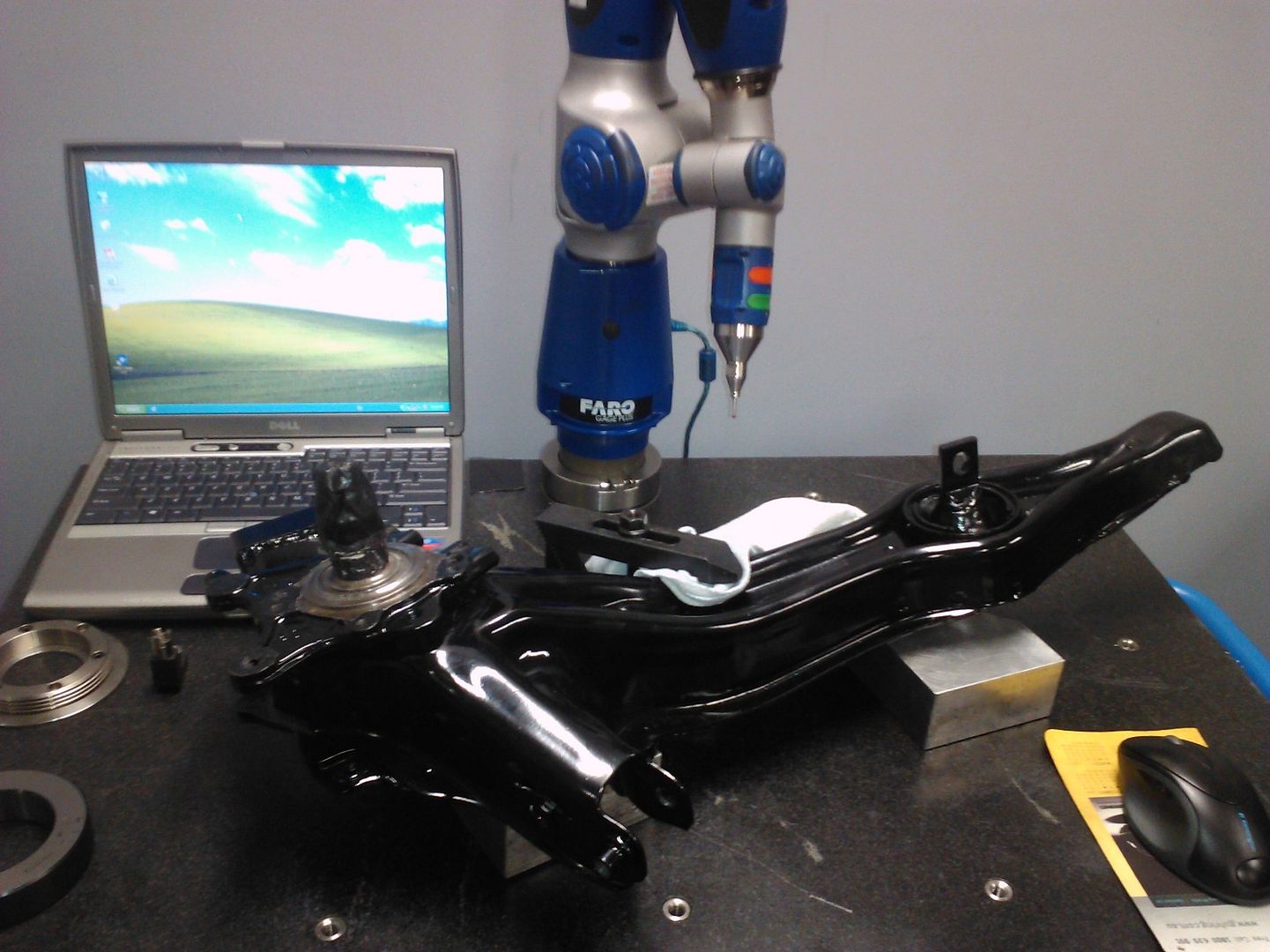

. Here's the SS Works car I mentioned:

. Here's the SS Works car I mentioned:

Comment