DC5 FRONT LOWER CONTROL ARM BUSHING INSTALL

This is a guide to installing PCi spherical bearings into a steel DC5 LCA, but it will work equally well for Mugen hard rubber bushes or any of the other polyurethane options on the market. Not that I would recommend poly for the LCA but that is a story for another time. The process is the same for the JDM LCAs but be very careful of damaging them as the forces required to install and remove the bushes are significant. ClubITR and myself take no responsibility for any misadventures that may befall you if you attempt this DIY, please only proceed if you have all the right tools and adequate mechanical knowledge.

Things you will need:

Jack

Jack stands

A press (Mine is 20 ton and did the job well)

Various bits of pipe and metal to press the bushes in and out

A ball joint puller (I used the Honda OEM tool part number: 07MAC-SL00200)

An M12x1.25 nut

Pliers

Allen keys

19mm socket

17mm socket

14mm spanner

Breaker bar/ratchet

Torque wrench

Various 1/2" extensions

Drill

A 1+3/4" hole saw

Duct tape

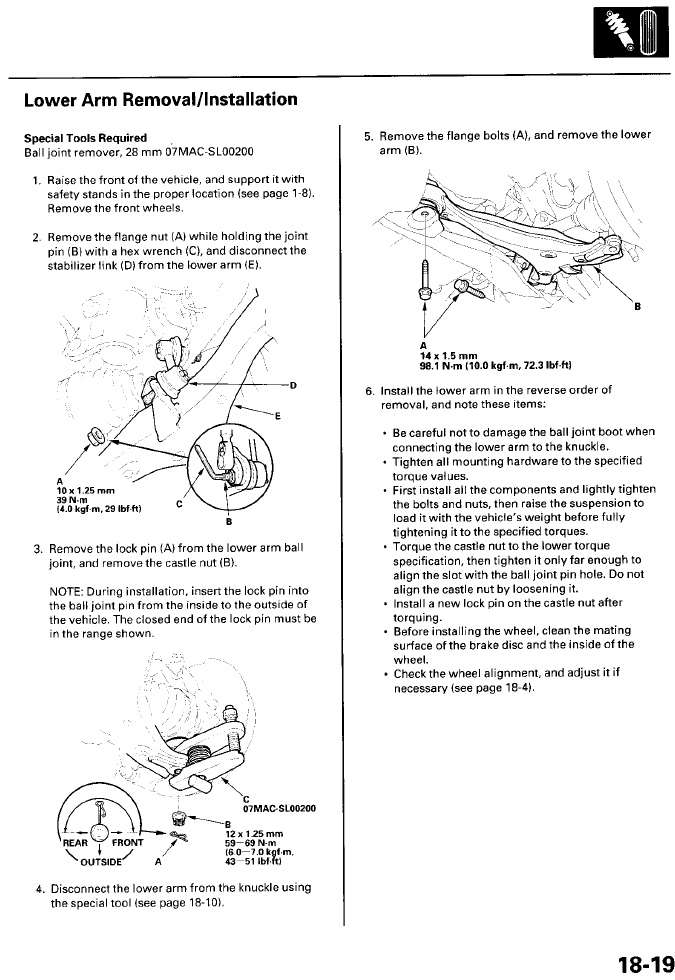

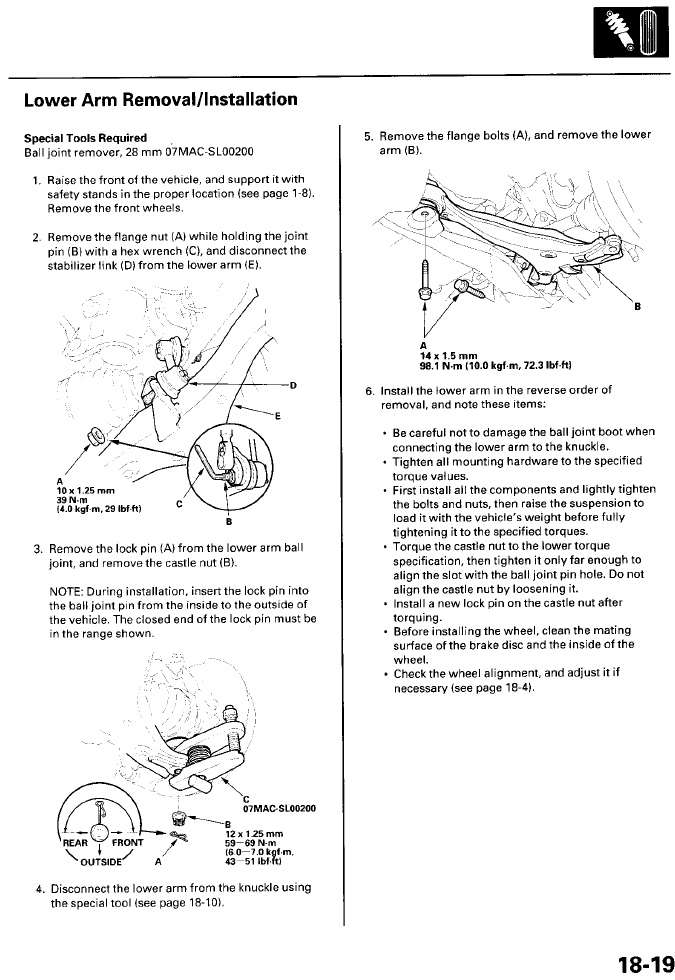

Figure 1: The relevant page from the workshop manual

Step 1: Using a breaker bar and a 19mm socket (if you have OEM wheel nuts) loosen the front wheel nuts. Raise the front of the car up using the jack and place the two jack stands under the two front jack points. Remove both front wheels, and you should be faced with something like what is pictured in Figure 2.

Step 2: Loosen but don't remove the two large bolts holding the lower control arm to the subframe, pictured toward the left of Figure 3, using a breaker bar and 19mm socket, refer to Figures 4 and 5. Loosen and remove the flange nut from the swaybar endlink with the 14mm spanner, using an allen key to prevent the link from spinning if necessary. Refer to Figure 6.

Figure 2: The car raised up

Figure 3: The lower control arm

Figure 4: Removing the front LCA bolt

Figure 5: Removing the rear LCA bolt

Figure 6: Removing the swaybar end link

Step 3: Using pliers remove the lock pin from the castle nut on the lower ball joint and loosen the castle nut using a breaker bar and 17mm socket, refer to Figure 7. Remove the castle nut from the ball joint stud and then put the M12x1.25 nut on in it's place threaded on until the bottom of the nut is level with the end of the stud. This is to protect the thread as you pop the ball joint out of the LCA.

Place your ball joint puller of choice on the ball joint as shown in Figure 8 and crank away on it with a 19mm spanner until the ball joint pops, taking care not to damage the threads. A few taps on the side of the LCA with a flat punch or drift and hammer sometimes helps the balljoint pop free.

Step 4: Once you have popped the balljoint then completely remove the 2 bolts into the subframe and remove the LCA from the car. Repeat the above steps for the other side of the car which should leave you with 2 lower control arms as pictured in Figure 9.

Figure 7: Removing the ball joint castle nut

Figure 8: Popping the ball joint

Figure 9: Lower control arms removed from car

This is a guide to installing PCi spherical bearings into a steel DC5 LCA, but it will work equally well for Mugen hard rubber bushes or any of the other polyurethane options on the market. Not that I would recommend poly for the LCA but that is a story for another time. The process is the same for the JDM LCAs but be very careful of damaging them as the forces required to install and remove the bushes are significant. ClubITR and myself take no responsibility for any misadventures that may befall you if you attempt this DIY, please only proceed if you have all the right tools and adequate mechanical knowledge.

Things you will need:

Jack

Jack stands

A press (Mine is 20 ton and did the job well)

Various bits of pipe and metal to press the bushes in and out

A ball joint puller (I used the Honda OEM tool part number: 07MAC-SL00200)

An M12x1.25 nut

Pliers

Allen keys

19mm socket

17mm socket

14mm spanner

Breaker bar/ratchet

Torque wrench

Various 1/2" extensions

Drill

A 1+3/4" hole saw

Duct tape

Figure 1: The relevant page from the workshop manual

Step 1: Using a breaker bar and a 19mm socket (if you have OEM wheel nuts) loosen the front wheel nuts. Raise the front of the car up using the jack and place the two jack stands under the two front jack points. Remove both front wheels, and you should be faced with something like what is pictured in Figure 2.

Step 2: Loosen but don't remove the two large bolts holding the lower control arm to the subframe, pictured toward the left of Figure 3, using a breaker bar and 19mm socket, refer to Figures 4 and 5. Loosen and remove the flange nut from the swaybar endlink with the 14mm spanner, using an allen key to prevent the link from spinning if necessary. Refer to Figure 6.

Figure 2: The car raised up

Figure 3: The lower control arm

Figure 4: Removing the front LCA bolt

Figure 5: Removing the rear LCA bolt

Figure 6: Removing the swaybar end link

Step 3: Using pliers remove the lock pin from the castle nut on the lower ball joint and loosen the castle nut using a breaker bar and 17mm socket, refer to Figure 7. Remove the castle nut from the ball joint stud and then put the M12x1.25 nut on in it's place threaded on until the bottom of the nut is level with the end of the stud. This is to protect the thread as you pop the ball joint out of the LCA.

Place your ball joint puller of choice on the ball joint as shown in Figure 8 and crank away on it with a 19mm spanner until the ball joint pops, taking care not to damage the threads. A few taps on the side of the LCA with a flat punch or drift and hammer sometimes helps the balljoint pop free.

Step 4: Once you have popped the balljoint then completely remove the 2 bolts into the subframe and remove the LCA from the car. Repeat the above steps for the other side of the car which should leave you with 2 lower control arms as pictured in Figure 9.

Figure 7: Removing the ball joint castle nut

Figure 8: Popping the ball joint

Figure 9: Lower control arms removed from car

Comment